Screen printing techniques are the foundation of creating durable, vibrant custom apparel and promotional products that make your brand stand out. Whether you’re planning a corporate event, launching a new product line, or need team uniforms on a tight deadline, choosing the right technique can make or break your project.

The six main screen printing techniques are:

- Spot Color – Solid, vibrant colors using PMS inks (best for logos and simple designs)

- Halftone – Creates gradients and shading effects with dot patterns

- Grayscale – Black and white photographic reproductions

- Duotone – Two-color halftones for vintage or artistic effects

- CMYK Process – Full-color printing using cyan, magenta, yellow, and black

- Simulated Process – Combines spot colors with halftones for photorealistic prints on dark garments

Screen printing has been the go-to method for custom apparel since ancient China, evolving from silk mesh to today’s precision polyester screens. The global custom t-shirt printing market, dominated by screen printing, is valued at over $3.64 billion and growing fast.

What makes screen printing so popular? Durability. Screen printed designs can be up to 50% more durable than digital prints when properly heat-cured. Plus, it’s incredibly cost-effective for bulk orders – the more you print, the less each piece costs.

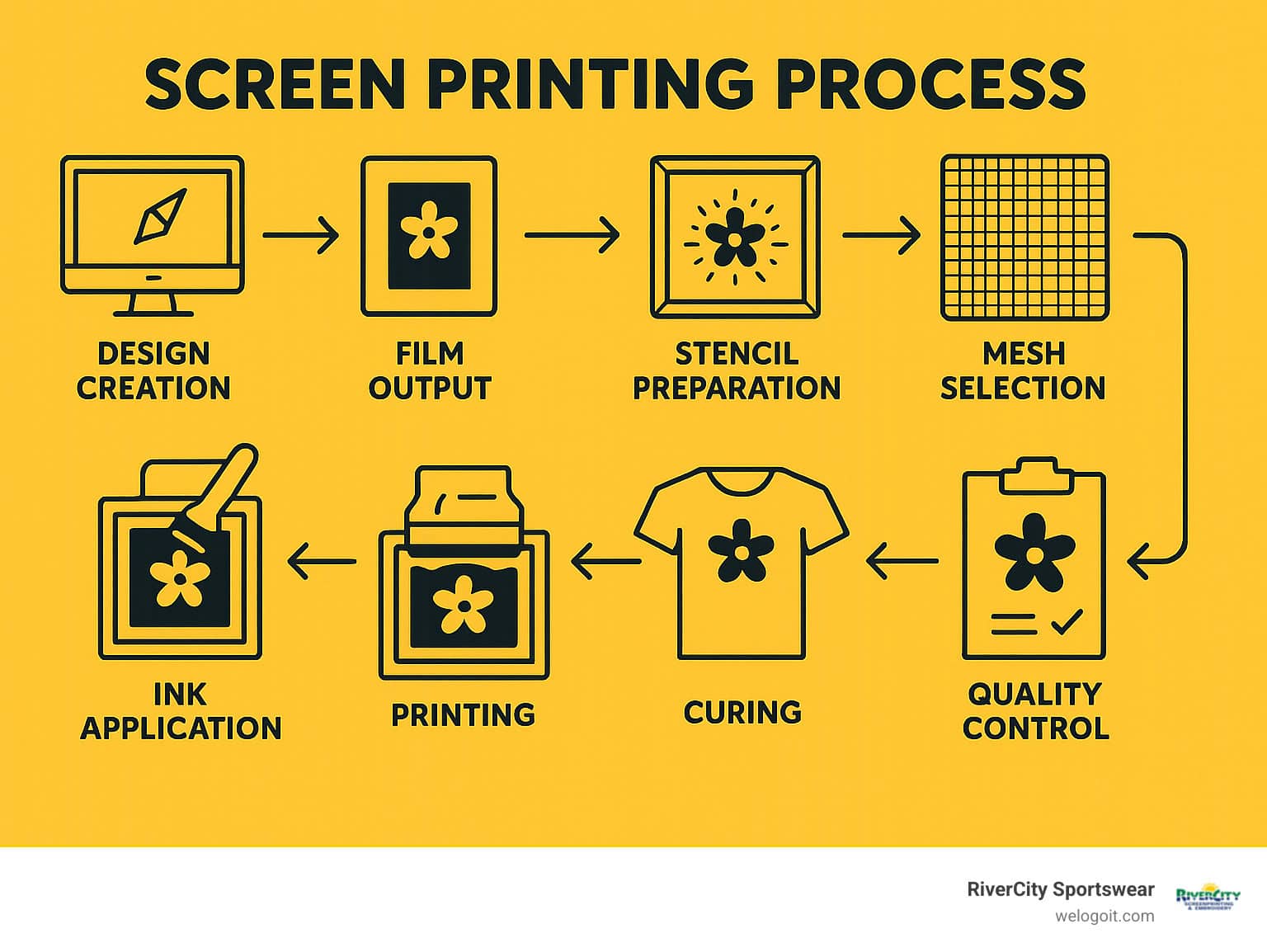

How Screen Printing Works: From Design to Curing

Screen printing techniques work like a sophisticated stencil system, where ink passes through open mesh areas while blocked sections create your design.

Every project starts with design creation. We transform your artwork into film positives – high-contrast negatives where your design appears as solid black on clear film. Each color needs its own film positive, which is why planning multi-color jobs carefully saves time and money.

The magic happens during stencil creation using photosensitive emulsion. We coat a mesh screen with this light-sensitive liquid, place your film positive on top, then expose it to UV light. The emulsion hardens everywhere except where your design blocks the light. After washing out the soft, unexposed emulsion, we’re left with a perfect stencil.

Registration becomes critical for multi-color work. Each screen must align precisely – even a millimeter off can ruin your project. The actual printing happens with the squeegee stroke at a 45-degree angle, forcing ink through the mesh onto your shirt.

Finally, curing sets everything permanently. Most plastisol inks cure around 150°C (300°F), while water-based inks need slightly lower temperatures. Proper curing means your prints will survive hundreds of washes without fading.

Step-by-Step Overview

Film positives come first. We separate your artwork by color and output each one onto transparent film at high resolution. Every color gets its own film, printed as solid black areas on clear material.

Coating the screens requires steady hands. Using a scoop coater, we apply photosensitive emulsion evenly across the mesh. The coated screen then dries in our light-safe room.

UV exposure bonds your design to the screen. We place your film positive against the dried emulsion and expose it with UV light for 8-15 minutes.

Wash-out reveals your stencil. After exposure, we rinse the screen with lukewarm water. The protected areas wash away easily, while UV-exposed areas stay hard.

Test proofs catch problems before they become disasters. We print samples to check registration, color accuracy, and print quality.

Production run brings everything together. Our automated presses handle up to 1,000 garments per hour for large jobs, while manual presses work perfectly for smaller runs.

Core Stencil-Making Methods

Hand-cut tape and vinyl work perfectly for simple shapes and bold designs. We cut masking tape or vinyl by hand and apply it directly to the screen. It’s quick and economical, but limited to basic shapes.

Photo-emulsion handles our most detailed work. This photosensitive method reproduces fine lines, halftones, and photographic detail with precision. We stock diazo emulsions (economical but slower), SBQ-based emulsions (fast exposing with excellent detail), and dual-cure emulsions (premium durability).

Scientific research on photosensitive emulsions

Screen Printing Techniques: Comprehensive Breakdown

Choosing the right screen printing techniques can transform your custom apparel from ordinary to extraordinary. Each technique has its sweet spot – some excel at bold corporate logos, others bring photographs to life, and specialty methods create effects that make people stop and ask, “How did you do that?”

Spot Colour Screen Printing Technique

When you need your logo to look exactly like your business cards, spot color printing is your best friend. We mix inks to match your exact Pantone colors, ensuring brand consistency whether it’s on paper or fabric.

Spot color works like painting with pure, undiluted paint. Each color needs its own screen, and the ink sits on top of the fabric as a smooth, vibrant layer. This is why spot colors look so bold and work beautifully on dark garments.

Corporate logos are perfect for this technique. Your company’s red will be exactly the same red every time. Team uniforms also shine with spot colors – those crisp numbers and bold team colors that won’t fade over time.

We use lower mesh counts (110-160) for spot colors because we want plenty of ink flowing through to create rich, opaque coverage. The beautiful part about cost: spot color gets cheaper the more you print.

Halftone & Grayscale Screen Printing Techniques

Halftone printing tricks your eye into seeing gradients and shadows using nothing but dots. With single-ink gradients, we can make one color look like ten. A red halftone creates everything from pale pink to deep crimson, all from one screen.

Grayscale printing takes this concept for photographs. Using just black ink on light garments, we can reproduce stunning portrait photography. It’s incredibly cost-saving since you only need one screen, but the results look expensive.

We typically use 35-65 LPI for textiles with mesh counts of 230-305 to capture those delicate dot patterns.

Duotone Screen Printing Technique

Duotone printing brings that sophisticated, vintage look that makes people think of classic concert posters. We create two-ink halftones – usually black for shadows and one color for midtones and highlights.

This technique works beautifully with mesh counts of 230+ for fine detail. Perfect for clients who want something special but don’t have the budget for full-color printing.

CMYK & Simulated Process Screen Printing Techniques

CMYK process printing uses four-colour separations – Cyan, Magenta, Yellow, and Key (black). These transparent inks overlap to create every color in the spectrum. It works great on light shirts where the white fabric helps colors stay true.

Simulated process becomes our secret weapon. Instead of being limited to four inks, we might use 8, 10, or even 12 screens to recreate complex images. We can print on dark garments by adding white underbase layers, and we often add extra spot highlights for colors that need to really pop.

Specialty & Effect Inks

Specialty inks create effects that make people reach out and touch your designs.

Discharge inks are perfect for large designs on dark shirts. These water-based inks actually bleach out the garment’s color and replace it with your design. The result feels like part of the fabric – incredibly soft.

Plastisol inks remain our workhorse. Puff ink expands when heated, creating raised designs. Glitter inks add sparkle. Foil applications create premium metallic finishes.

High-density inks build up thick, tactile surfaces perfect for athletic numbers. Glow-in-the-dark inks charge up under light for cool nighttime effects.

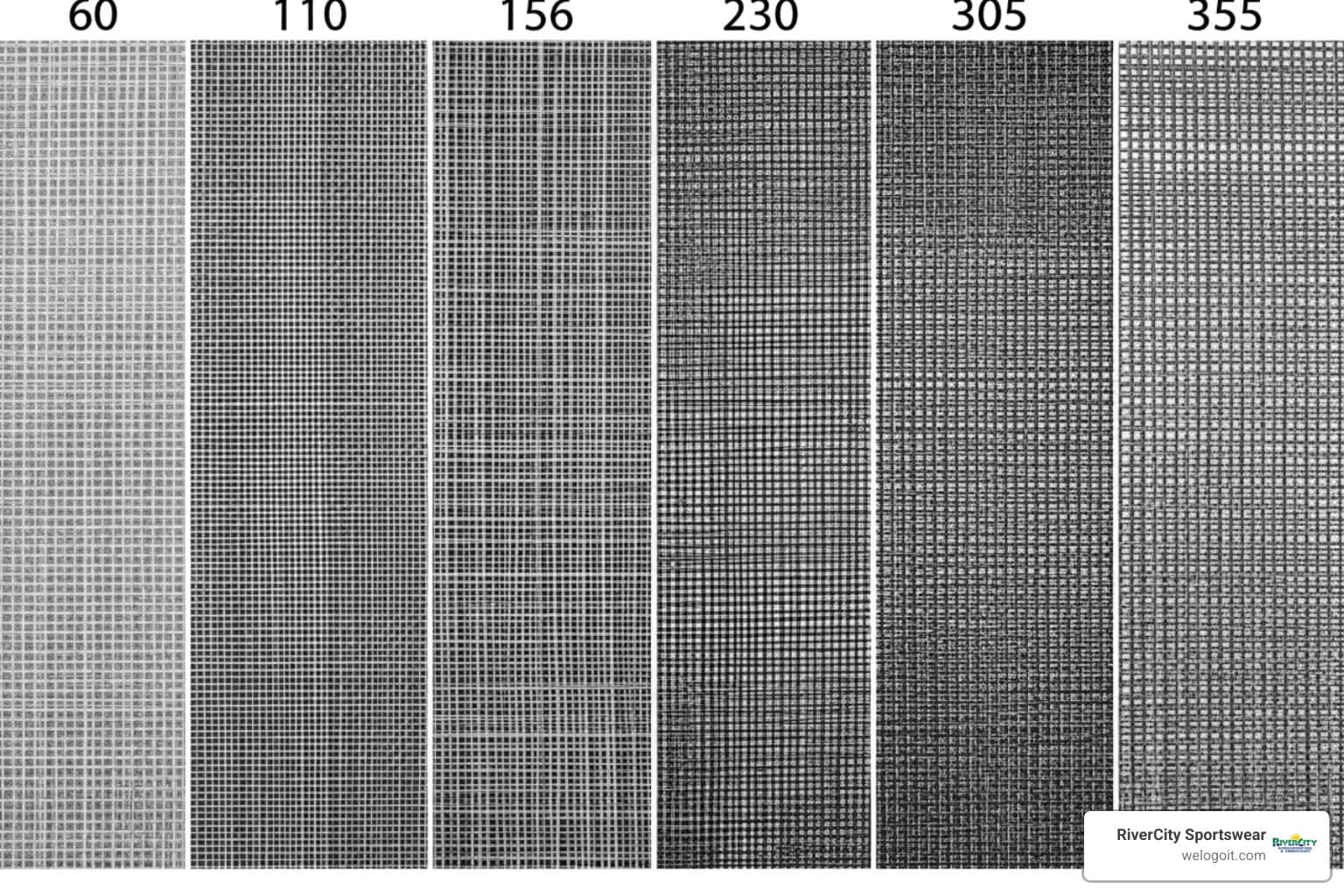

Materials, Mesh Counts & Equipment Essentials

Smart material choices make the difference between good prints and great ones. Polyester is our go-to mesh material for 90% of our jobs. It holds consistent tension, resists chemicals, and won’t break the bank. Stainless steel mesh is the premium choice for massive runs where durability is everything.

The mesh count determines what you can print effectively. Lower mesh counts (40-86) have big openings for heavy coverage with specialty inks. Medium counts (110-160) handle most spot color work. Higher counts (200-230) give you fine detail for halftones. Ultra-fine mesh (280-305) produces thin ink deposits and crisp detail.

| Mesh Count | Best For | Ink Deposit | Detail Level |

|---|---|---|---|

| 40-86 | Heavy ink coverage, glitter | Very Heavy | Low |

| 110-160 | Spot colors, bold graphics | Heavy | Medium |

| 200-230 | Fine detail, halftones | Medium | High |

| 280-305 | Ultra-fine detail, thin inks | Light | Very High |

We use aluminum frames because they maintain consistent tension over thousands of prints. Squeegee selection affects results dramatically. Soft squeegees (60-70 durometer) flex more, ideal for heavy ink deposits. Hard squeegees (80-90 durometer) stay rigid, giving crisp edges and thin ink films.

Choosing the Right Mesh & Tension

Proper tension is critical for consistent results. We measure tension in Newtons per centimeter using calibrated tension meters. Most polyester mesh performs best at 20-25 N/cm tension.

The eternal trade-off is ink deposit versus detail. Want that bold logo on black shirts? You’ll need lower mesh counts that deposit plenty of ink. Need crisp halftones? Higher mesh counts give sharp detail but lighter coverage.

Essential Press & Dryer Options

Carousel presses are the workhorses of apparel printing. Manual carousel presses require skilled operators but give maximum control. Automatic presses can run at incredible speeds but require precise setup.

Production speed varies dramatically. Manual presses typically produce 60-100 pieces per hour. Automatic carousel presses can handle up to 1,000 garments per hour on long runs.

Curing equipment is where you cannot compromise. Plastisol inks must reach 150°C (300°F) throughout the entire ink film. We use conveyor dryers with precise temperature control and verify cure temperatures on every job.

Benefits, Challenges & Sustainable Best Practices

Screen printing techniques offer incredible advantages but aren’t perfect for every situation. The durability factor alone makes screen printing worth considering. Properly cured screen prints can outlast the garment itself – we regularly hear from customers whose 10-year-old prints still look brand new.

Vibrancy is another game-changer, especially on dark fabrics. Screen printing inks sit on top of fabric with incredible opacity, making colors absolutely pop. The bulk economy aspect is where screen printing really shines – cost-per-piece can drop by 70% when increasing orders from 50 to 500 pieces.

Substrate versatility keeps surprising people. We’ve printed on canvas bags, plastic signs, metal panels, and wooden promotional items. Different inks and techniques let us adapt to almost any surface.

Now for the challenges. Setup time creates minimum order requirements. Color limitations can catch people off guard – each color traditionally needs its own screen. However, techniques like simulated process let us create full-color effects more economically.

Difference: Screen Printing vs. Heat Press

Tips for High-Quality Results

Great screen printing comes down to attention to detail. Proper artwork preparation makes or breaks a job. We prefer vector files when possible, but high-resolution images at 300 DPI work well too.

Mesh tension checks happen before every job. Loose screens cause registration nightmares and muddy print quality. Test proofs are non-negotiable – they catch problems before they become expensive disasters.

Heat cure verification closes out every job properly. We use infrared thermometers to ensure inks reach the right temperature throughout the entire ink film.

Environmental Considerations

Sustainability matters to our clients and community. Water-based inks have become increasingly popular – they’re PVC-free, phthalate-free, and feel amazing on skin.

Chemical management is serious business. We properly dispose of screen reclaim chemicals and actively seek eco-friendly alternatives. Energy efficiency improvements include LED exposure units and efficient conveyor dryers.

Screen recycling extends material life considerably. Aluminum frames can last for years with proper care, and we reclaim and reuse screens whenever possible.

Scientific research on PVC-free inks

Frequently Asked Questions about Screen Printing Techniques

What mesh count should I use for photographic detail?

For photographic reproduction, we typically use 230-305 mesh count screens. Higher mesh counts capture finer detail, but there’s a trade-off with ink opacity on dark garments.

How many washes does a plastisol print last?

Properly cured plastisol prints easily handle 50+ wash cycles with minimal fading. We’ve stress-tested prints through 100+ cycles and they still look fantastic.

Can I print complex artwork on dark garments?

Absolutely! Simulated process printing reproduces photographic images on dark shirts using 6-12 screens to build up the complete image with proper highlights and shadows.

Conclusion & Next Steps

Choosing the right screen printing technique can transform your custom apparel from ordinary to extraordinary. Whether you’re printing simple logos with spot color, creating vintage effects with duotone, or reproducing full-color photographs with simulated process, understanding these techniques helps you make smarter decisions for your business.

What sets us apart? We combine exceptional customer service with technical expertise and honest advice. When a client comes to us with a complex design, we look at your goals, timeline, and budget to recommend the technique that delivers the best results for your specific situation.

Fast turnaround times matter when you’re facing a deadline. Our streamlined workflow can handle rush orders without sacrificing quality. We’ve printed last-minute event shirts, emergency uniform replacements, and time-sensitive promotional items.

Personalized design support means we’re here from concept to delivery. Our design team reviews your artwork, suggests improvements, and ensures your chosen screen printing techniques will produce the results you envision.

Here’s what you should remember: Spot color delivers vibrant, durable results for logos. Halftone and grayscale techniques give you photographic effects without breaking the budget. Simulated process creates stunning full-color prints on any garment color. The key is matching the technique to your specific needs.

The best screen printing technique is always the one that fits your project perfectly – not the most complex or expensive option.

Ready to see what screen printing techniques can do for your next project? We serve businesses throughout Central and South Texas. Whether you need corporate uniforms, event merchandise, or promotional apparel, we have the expertise and equipment to exceed your expectations.

Contact us today to discuss your project. Let’s explore which techniques will work best for your timeline, budget, and quality goals.

More info about our Screen Printing