Getting Started with Screen Printing Materials

Materials used in silkscreen printing are the foundation of this versatile printing technique that allows you to transfer ink onto virtually any flat surface. Whether you’re printing custom t-shirts, posters, or promotional products, having the right supplies is crucial for quality results.

Here’s a quick overview of the essential materials needed for silkscreen printing:

| Material Category | Essential Items |

|---|---|

| Screens & Frames | Mesh screens (110-305 count), aluminum or wooden frames |

| Inks | Plastisol, water-based, discharge, specialty inks |

| Squeegees | Polyurethane blades (60-90 durometer) |

| Stencil Materials | Emulsion, capillary film, scoop coater |

| Exposure Equipment | UV light source, exposure unit |

| Curing Equipment | Flash dryer, conveyor dryer, heat press |

| Accessories | Screen tape, pallet adhesive, cleaning chemicals |

Silkscreen printing (also called screen printing or serigraphy) is an ancient technique that has evolved into one of the most versatile printing methods in the world. What began with silk mesh stretched over wooden frames in ancient China is now a sophisticated process using modern materials and technology.

The beauty of screen printing lies in its simplicity and versatility. With the right materials, you can print on almost anything—from t-shirts and tote bags to posters, signage, and even electronic circuit boards.

What makes screen printing unique is how the ink sits on top of the substrate rather than being absorbed (except with certain ink types like discharge). This creates vibrant, opaque prints that stand out—especially on dark materials where other printing methods might fall short.

Why Choosing the Right Materials Used in Silkscreen Printing Matters

Have you ever wondered why some printed t-shirts look vibrant after dozens of washes while others fade after just a few? The secret lies in the materials. As someone who’s seen thousands of prints come to life, I can tell you that the materials used in silkscreen printing aren’t just items on a shopping list—they’re the foundation of everything that follows.

Your choice of materials directly impacts five crucial aspects of your prints:

- Print durability: Quality materials create prints that last through countless wash cycles

- Color vibrancy: The right inks and mesh combinations produce eye-catching, bold colors

- Production speed: Good materials flow smoothly through your process, reducing delays

- Cost efficiency: Premium materials reduce waste and reprints in the long run

- Environmental impact: Today’s best materials are designed with safety and sustainability in mind

How the materials used in silkscreen printing influence every step

Screen printing is like a dance where every partner needs to move in perfect harmony:

Ink viscosity must match your mesh count perfectly. Thick, creamy inks need lower mesh counts (110-156) to flow through properly, while thinner inks work beautifully with higher mesh counts (200+) for detailed designs.

Mesh tension is another critical factor. A screen that’s too loose will create blurry edges, while one that’s too tight risks tearing during production.

The relationship between curing temperatures and ink types is perhaps the most crucial. Each ink has its specific curing requirements to ensure durability without damaging the fabric.

Key performance statistics at a glance

For mesh count, the standard range is 110-305 threads per inch. Most shops find that 156-230 is the sweet spot for everyday printing. Lower counts (110-156) are perfect for laying down thick ink deposits on dark garments, while higher counts (230-305) excel at capturing fine details and halftones.

When selecting a squeegee, durometer (hardness) matters tremendously. The scale runs from 60 (soft) to 90 (hard), with 70-75 being the most versatile for general purpose printing.

For curing temperatures, plastisol ink typically needs to reach 320°F for about 45 seconds to achieve a complete cure. Water-based inks usually require around 330°F for 60-90 seconds.

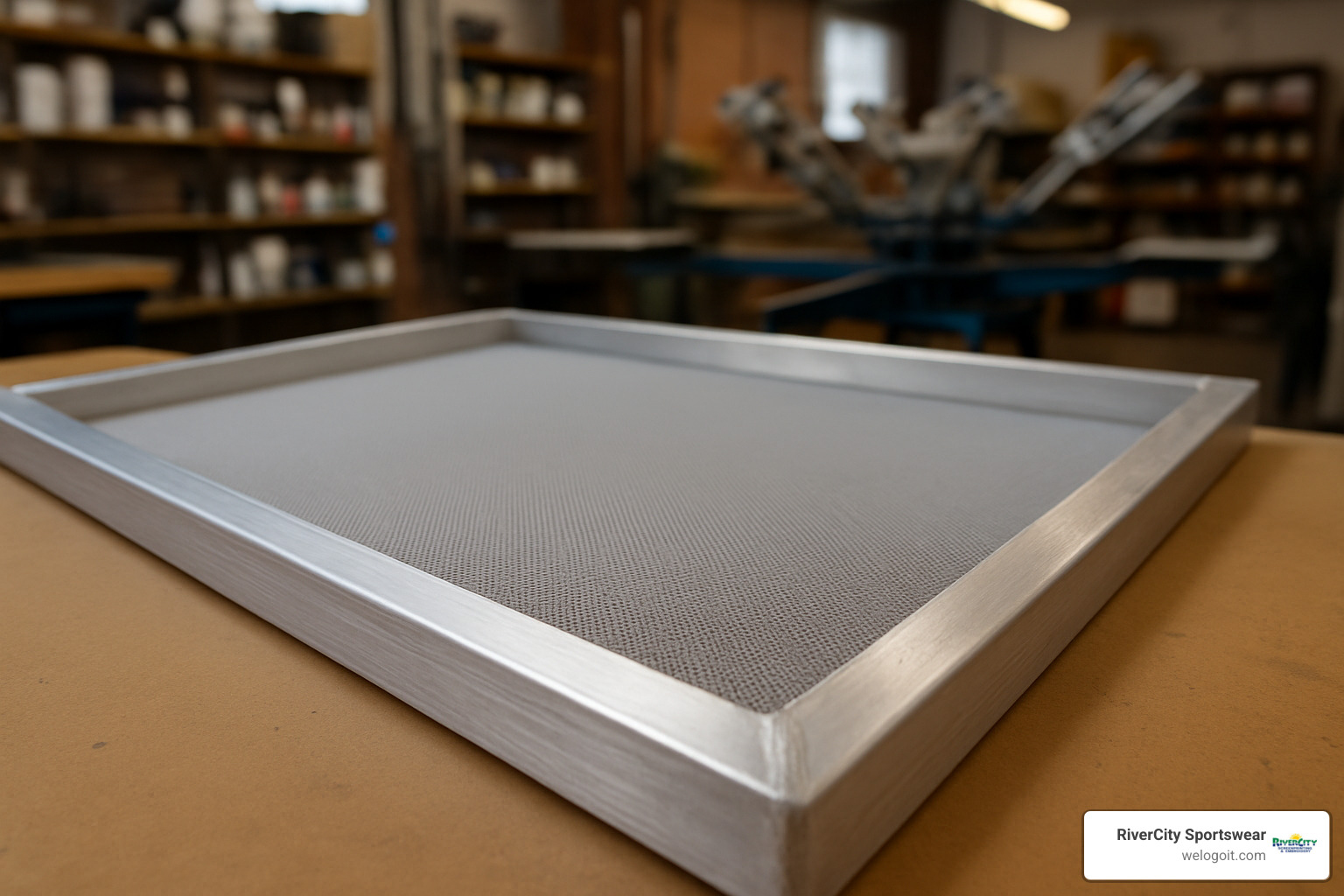

Mesh Screens & Frames: The Backbone of Every Print

The screen is where the magic begins in silkscreen printing. Despite the name, modern screens rarely use actual silk—though that’s where the technique originated centuries ago.

Today’s materials used in silkscreen printing have evolved significantly. Most professional printers now use polyester mesh as the industry standard because it maintains tension beautifully and stands up to repeated use. For specialized applications, stainless steel mesh offers extreme precision, while nylon mesh finds its place in certain specialty applications.

The frame holding your mesh isn’t just a support structure—it’s a crucial part of your printing foundation. Here’s how the two main options stack up:

| Frame Type | Advantages | Disadvantages | Best For |

|---|---|---|---|

| Wood | Lower cost, lighter weight | Warps with water exposure, shorter lifespan | Beginners, hobbyists, small runs |

| Aluminum | Warp-resistant, longer lifespan, holds tension better | Higher initial cost, heavier | Professional shops, large runs, water-based inks |

Dialing-in Mesh Count for Detail or Coverage

Mesh count refers to the number of threads per inch in your screen fabric, and it’s truly the unsung hero of print quality.

- 110 mesh: Perfect for bold athletic numbers or bright white ink on dark shirts

- 156 mesh: Versatile workhorse for most standard designs

- 200 mesh: Ideal balance between detail and ink deposit

- 230 mesh: Captures fine lines or halftones while still laying down enough ink

- 305 mesh: Delivers the finest detail possible for four-color process printing

Having screens in 156, 200, and 230 mesh counts will handle about 90% of typical jobs for most shops.

Frame Material Showdown—Wood vs Aluminum

Wood frames are budget-friendly, lightweight for manual printing, and naturally absorb vibration during the print stroke. The downside? They’re prone to warping and typically need replacement every 6-12 months with regular use.

Aluminum frames, while requiring a bigger upfront investment, provide superior stability and resistance to warping. When mesh inevitably loosens with use, aluminum frames can be professionally retensioned rather than replaced, making them more economical long-term.

Prep & Cleaning Essentials for Reusable Screens

Proper screen care directly impacts the quality of every print you produce. You’ll need quality degreasers to remove oils, effective reclaiming chemicals to prepare screens for reuse, and haze removers for stubborn ghost images.

Ink Options: From Plastisol to Eco-Friendly Alternatives

The ink you choose is perhaps the most visible aspect of your materials used in silkscreen printing. Different inks create different looks, feels, and durability levels—and the right choice can make or break your project.

Plastisol—The Industry Workhorse

Plastisol is made of PVC particles suspended in plasticizers—which is a fancy way of saying it’s a plastic-based ink that sits on top of your fabric. What makes it so popular? It doesn’t dry in your screen, produces incredibly vibrant colors, and offers excellent opacity on dark garments.

Plastisol requires heat (320°F for about 45 seconds) to fully cure, but once properly set, these prints will outlast the garment itself in many cases. Specialized variations include bleed blockers that prevent dye migration from polyester garments and high-opacity formulas for dark shirts.

The main drawback? That slight plastic feel on the garment. You can learn more about the various types of ink used in screen printing.

Water-Based & Discharge for Soft-Hand Prints

Water-based inks contain pigments suspended in water with binders that penetrate the fabric rather than sitting on top. The result is an incredibly soft, breathable print that becomes part of the garment.

The trade-off? Water-based inks can dry in your screen (sometimes mid-print), generally offer less opacity on dark garments, and require higher cure temperatures (around 330°F) and longer dwell times (60-90 seconds).

Discharge inks are a special subset of water-based inks that actually remove the garment’s dye and replace it with the ink color. The result is a print that’s literally part of the fabric—zero feel, beautiful results.

Curious about water-based printing? Check out our detailed explanation of what exactly water-based ink is in screen printing.

Specialty & Effect Inks That Wow

Specialty inks create unique effects that make prints stand out:

- Puff ink: Expands when heated, creating a raised texture

- High-density ink: Creates dramatic 3D effects through extremely thick ink deposits

- Metallic inks: Contain actual metal particles for a reflective finish

- Glitter inks: Embed sparkle particles that catch the light

- Glow-in-the-dark: Illuminates in dark venues after charging in daylight

- Suede ink: Creates a soft, velvety texture

| Ink Type | Best Mesh Count | Cure Temp | Cure Time | Feel on Fabric |

|---|---|---|---|---|

| Plastisol | 110-230 | 320°F | 45 sec | Slight hand |

| Water-based | 156-305 | 330°F | 60-90 sec | Minimal/none |

| Discharge | 156-230 | 330°F | 60-90 sec | None |

| Puff | 110-156 | 330°F | 60 sec | Raised |

| High-density | 86-110 | 320°F | 60-90 sec | Very raised |

| Metallic | 110-156 | 320°F | 45-60 sec | Slight hand |

Squeegees: Your Precision Ink-Delivery Tool

The humble squeegee might look simple, but in screen printing, it’s your magic wand. This essential tool controls exactly how much ink passes through your screen and determines the quality of your final print.

Modern professional squeegees typically include:

- A polyurethane blade (which has largely replaced rubber for its durability)

- An ergonomic handle made from wood, aluminum, or composite materials

- A mounting system that secures the blade to the handle

Durometer Guide for Every Substrate

Durometer is the “hardness rating” of your squeegee blade, and different printing jobs call for different durometers:

Soft squeegees (60-65 durometer) feel almost rubbery to the touch. They’re perfect when you need to lay down a thick layer of ink—like when printing bold white ink on black shirts. They conform nicely to textured fabrics, making them ideal for flooding your screen or when you need maximum ink coverage.

Medium squeegees (70-75 durometer) are the Goldilocks of the screen printing world—not too soft, not too hard. This is our go-to range for most jobs. They offer that sweet spot of ink deposit and control that works beautifully for standard applications.

Hard squeegees (80-90 durometer) are firm and precise. When we’re printing detailed logos with fine lines or halftones, we reach for the harder durometers. They deposit less ink but with greater precision, making them perfect for smooth surfaces like paper, plastic, or glass.

Blade Geometry—Square vs Round vs Bevel

The shape of your squeegee’s edge is just as important as its hardness:

Square edge squeegees are the workhorses of the industry. They provide an even ink deposit and create clean, crisp edges in your prints. When we’re printing most standard orders at RiverCity, square edges are our default choice.

Round edge squeegees allow more ink to flow under the blade during your print stroke. This profile is great when you need a heavier ink deposit or when printing on uneven surfaces where a square edge might skip.

Beveled edge squeegees have an angled profile that creates directional printing characteristics. These are specialty tools we might pull out for printing on glass, ceramic, or other challenging surfaces where the angle helps control ink flow in specific ways.

For most custom apparel work, we stick with square-edge squeegees in the 70-75 durometer range. This combination gives us versatile performance across everything from cotton tees to polyester jerseys.

Emulsions, Stencils & Light-Exposure Gear

Creating the stencil is perhaps the most technical aspect of screen printing, requiring precise materials used in silkscreen printing to achieve sharp, durable images.

Picking the Right Emulsion for Your Ink Type

Emulsion transforms your mesh into a printable stencil. There are several types to choose from:

Diazo emulsions are forgiving for beginners. You’ll mix a sensitizer with the base, giving you a two-part system. While they take longer to expose (sometimes 5-10 minutes), they give you more wiggle room if your timing isn’t perfect.

Presensitized (SBQ) emulsions come ready to use straight out of the container—no mixing required! These expose much faster (often in 30-90 seconds) and capture fine details exceptionally well, though they’re more light-sensitive.

Dual-cure emulsions combine diazo and presensitized technologies. They provide durability for long print runs in warm, humid conditions and resist solvents well, which is crucial when working with plastisol or solvent-based inks.

Capillary film offers consistency that’s hard to beat. Rather than coating liquid emulsion onto your screen, you apply these pre-manufactured sheets to a wet screen, creating incredibly precise stencils for detailed work.

Matching your emulsion to your ink is crucial—water-based inks need water-resistant emulsions, solvent-based inks require solvent-resistant formulations.

Creating Razor-Sharp Stencils

The journey from design to stencil requires several key materials working in harmony:

- Film positives: Transparent sheets with opaque black images that block light during exposure

- Exposure unit: Modern LED units provide the perfect 350-420 nanometer wavelength light that hardens emulsion

- Vacuum system: Creates tight contact between your positive and the screen, preventing light from bleeding under the edges

- Washout equipment: A gentle but steady spray is key for developing your stencil

For best results:

- Always degrease your mesh first—oils are emulsion’s enemy

- Use a scoop coater for even application

- Dry screens completely in a dust-free environment

- Make perfect contact between your positive and screen

- Time your exposure precisely

- Develop with gentle water pressure

In our production facility, we’ve learned that proper stencil preparation eliminates most printing headaches before they start.

Curing & Drying Equipment for Rock-Solid Prints

The curing process is where screen printing magic becomes permanent. Without proper curing, even the most beautiful print job will quickly fade, crack, or wash away in the laundry.

Nailing the Perfect Cure Every Time

Different ink systems need specific curing approaches to become permanent:

- Plastisol ink: Needs to reach 320°F throughout the entire ink deposit for at least 45 seconds

- Water-based inks: Typically require higher temperatures around 330°F and longer dwell times of 60-90 seconds

- Discharge inks: Follow similar guidelines to water-based inks but sometimes need even longer in the dryer

- Specialty inks: Often have unique requirements—puff ink, for example, needs precise temperature control to expand properly

To ensure proper curing, several tools are essential:

- Temperature strips: One-time use indicators that change color to show peak temperature

- Infrared thermometers: Give quick surface temperature readings

- Donut probe: Measures both surface and internal temperature as it passes through your dryer

- Wash test: The ultimate test—run a print through several wash cycles to verify durability

Budget vs Production-Scale Solutions

Curing equipment options scale with your business:

Heat press: Often where beginners start. It’s affordable and gives precise temperature control, but it’s slow since you cure one print at a time.

Flash dryer: The Swiss Army knife of screen printing heat sources. Primarily designed to “flash” a layer of ink during multi-color printing, but can fully cure small runs in a pinch.

Conveyor dryer: Essential for production work. These move prints through a heated chamber on a belt, ensuring consistent temperature and dwell time for every garment. They require more space, power, and initial investment, but are the gold standard for production.

Our production facilities rely on industrial conveyor dryers with precise temperature controls and variable belt speeds. This setup ensures perfect curing regardless of whether we’re printing cotton t-shirts for a local band or moisture-wicking performance wear for a school’s athletic department.

Essential Accessories, Safety & Sustainability Gear

Beyond the major components, a range of supplementary materials used in silkscreen printing makes the difference between struggling and working efficiently.

These accessories are the unsung heroes of your print shop:

- Pallet adhesive: Keeps garments from shifting during printing

- Screen tape: Blocks open areas of the screen and reinforces edges

- Ink spatulas: Essential for mixing colors and achieving perfect consistency

- Registration guides: Ensure colors line up perfectly in multi-color work

- Test pellon: Allows checking alignment and coverage without risking mistakes on actual products

- Cleanup cards: Quickly remove excess ink from screens between colors

Keeping Your Shop Safe & Green

Safety isn’t just a buzzword in screen printing—it’s essential for long-term success and wellbeing:

- Nitrile gloves: Protect hands from chemicals while maintaining dexterity

- Safety glasses: Essential at the reclaiming station to protect eyes from chemicals

- Respirators: Non-negotiable when working with solvents or reclaiming screens

- Ventilation systems: Protect health and make the workspace more comfortable

Environmental responsibility has become increasingly important. Our eco-conscious practices include:

- Carefully reclaiming screens for reuse

- Mixing only the ink needed for each job

- Switching to biodegradable cleanup products when possible

- Installing filtration systems to reclaim water used in screen washing

- Opting for eco-friendly alternatives that reduce our environmental footprint

Frequently Asked Questions about Materials Used in Silkscreen Printing

Which mesh count is best for beginners?

When you’re just starting your screen printing journey, a 156 or 160 mesh count screen is your best friend. Think of it as the “Goldilocks” of mesh counts – not too fine, not too coarse, but just right for most basic projects. This versatile mesh works beautifully with standard plastisol inks and handles everything from bold text to simple graphics with ease.

As your confidence grows, consider adding a 110 mesh for heavy ink coverage on dark shirts, and a 230 mesh for more detailed designs with finer lines and halftones.

Can I cure a print with a household iron?

While technically possible to cure small plastisol prints with a household iron, I’d strongly recommend finding another solution.

Irons have inconsistent heat distribution, making it nearly impossible to maintain the necessary 320°F temperature for the full 45 seconds needed for a proper cure. Without consistent heat, parts of your print may seem cured while others remain undercured, leading to cracking and washing issues.

If you’re on a budget but want more reliable results, a heat press is a worthwhile investment. It provides consistent temperature and pressure, giving you professional-quality cures without breaking the bank.

What’s the safest way to dispose of leftover ink?

For plastisol ink, which contains PVC, the safest approach is to fully cure it first by exposing it to proper heat. Once cured, it becomes a solid plastic that can be disposed of with regular solid waste in most areas.

With water-based ink, allow it to completely dry before disposal. The dry residue is typically safer to handle than wet ink.

When dealing with chemical waste like emulsion removers or screen cleaners, never pour these down drains! Contact your local hazardous waste facility for guidance on proper disposal methods in your area.

Many regions have specific regulations regarding ink and chemical disposal, so it’s worth checking your local requirements.

Wrapping Up: Your Silkscreen Printing Materials Mastery

Understanding the materials used in silkscreen printing isn’t just about memorizing a shopping list—it’s about building the foundation for prints that truly stand the test of time. Every choice you make, from mesh count to ink type, shapes the quality, durability, and visual impact of your final product.

Think of these materials as instruments in an orchestra—each plays its own vital role, but the magic happens when they work in perfect harmony. When your mesh tension complements your ink viscosity, when your squeegee durometer matches your substrate, and when your curing temperature hits that sweet spot for your ink system, you’ll create prints that consistently wow your customers.

At RCSE, we’ve spent years fine-tuning our material selections through countless print runs across Central and South Texas. We’ve learned that cutting corners on materials inevitably leads to cutting corners on quality. That’s why we’ve built our reputation on using only professional-grade supplies that deliver exceptional results time after time.

For those just starting their screen printing journey, investing in quality materials upfront saves frustration, wasted time, and disappointment down the road. Start with versatile basics and expand your arsenal as your skills and client needs grow.

The beauty of screen printing lies in its blend of technical precision and creative expression. The materials provide the science, but your artistic vision and craftsmanship bring each print to life. Master both aspects, and you’ll transform blank garments into walking canvases that advertise not just your client’s message, but your skill as a printer.

Ready to take your screen printing to the next level? Learn more about our professional screen-printing services or reach out to our team for personalized guidance on your next project.