Why Screen Printed Heat Transfers Are the Smart Choice for Custom Apparel

If you’re searching for “screen printed heat transfers near me,” you’re looking for a versatile and high-quality solution for custom apparel. Here’s what you need to know:

- What they are: Pre-printed designs using plastisol ink on release paper, ready to be applied with a heat press.

- Where to find them: Local print shops in San Marcos, Austin, and Central Texas, or online suppliers.

- Typical turnaround: 24-48 hours for rush orders, 2-3 business days for standard.

- Best for: Small to medium runs, on-demand printing, events, and team uniforms.

- Cost: Starts around $0.15-$0.20 per transfer, with lower per-unit costs for bulk orders.

- Application: Use a heat press at 310°F for 12-15 seconds.

Screen printed heat transfers offer professional-quality custom apparel without the large minimum order requirements or long lead times of traditional screen printing. Unlike direct-to-garment printing, these transfers can be stored indefinitely and applied only when you need them. This means you can order 100 transfers but press only 10 shirts today and save the rest for later, giving you total control over your inventory.

I’m Luke Sanders, CEO of RiverCity Sportswear, and I’ve spent over 15 years helping businesses across San Marcos, Austin, and Central Texas with their custom apparel needs. Our team has produced millions of high-quality transfers and is ready to help you find the perfect solution.

What Are Screen Printed Heat Transfers?

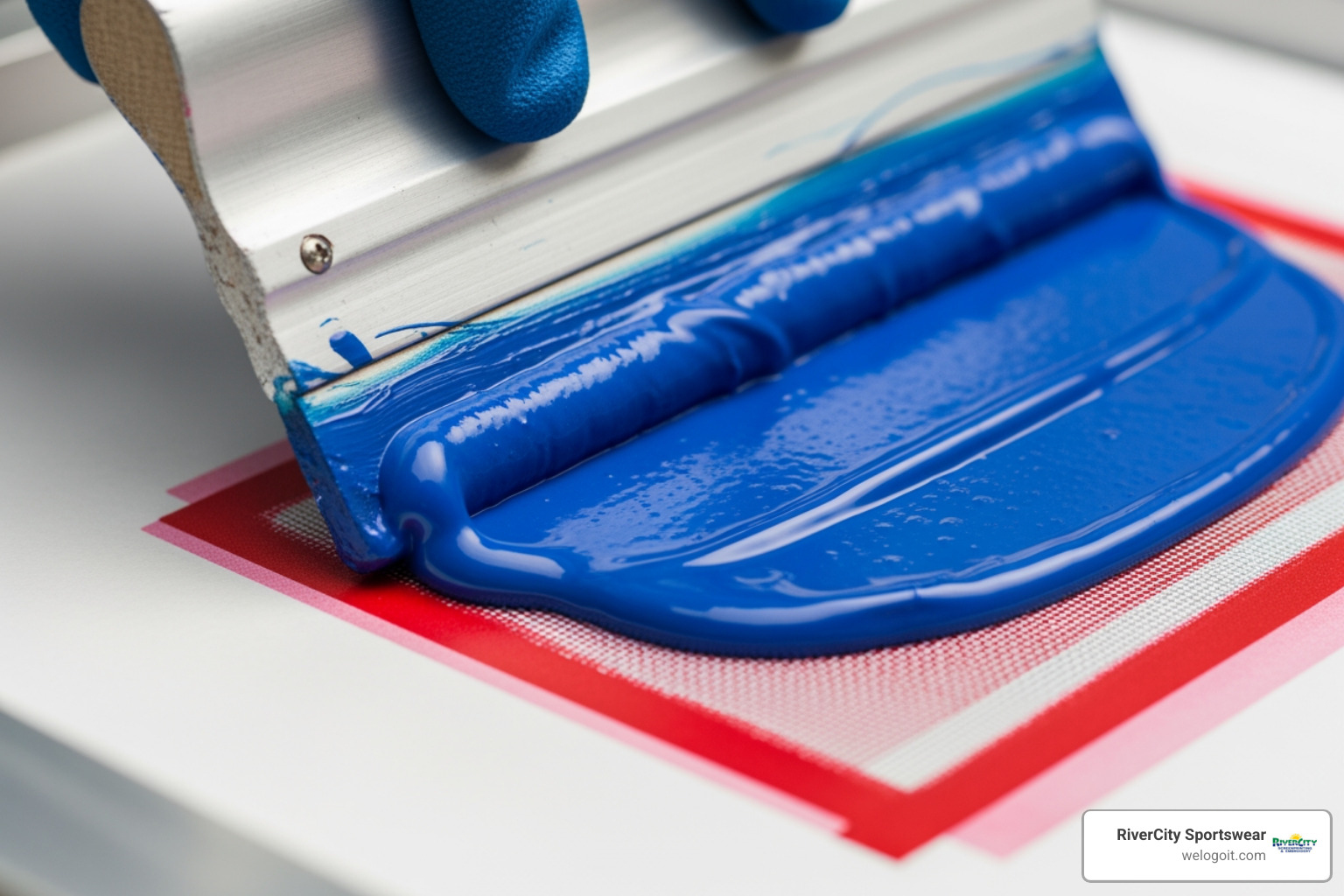

Screen printed heat transfers offer the high-quality look and feel of traditional screen printing with the flexibility of on-demand application. The process involves screen printing a design with plastisol ink—a durable, plastic-based ink—onto a special release paper, rather than directly onto a garment. This method uses the same techniques as traditional screen printing, where ink is pushed through a mesh screen to create the design. For a deeper dive into the mechanics, you can check out our guides on Screen printing explained, What Is Screen Printing?, and The Screen Printing Process.

Once the ink is on the release paper, an adhesive powder is applied, and the design is partially cured. This prepares the ink for its final destination: your apparel. These storable designs can be kept for extended periods, allowing for on-demand application. You can order transfers now and apply them as needed, which is a game-changer for businesses and organizations across San Marcos, Austin, and Central Texas.

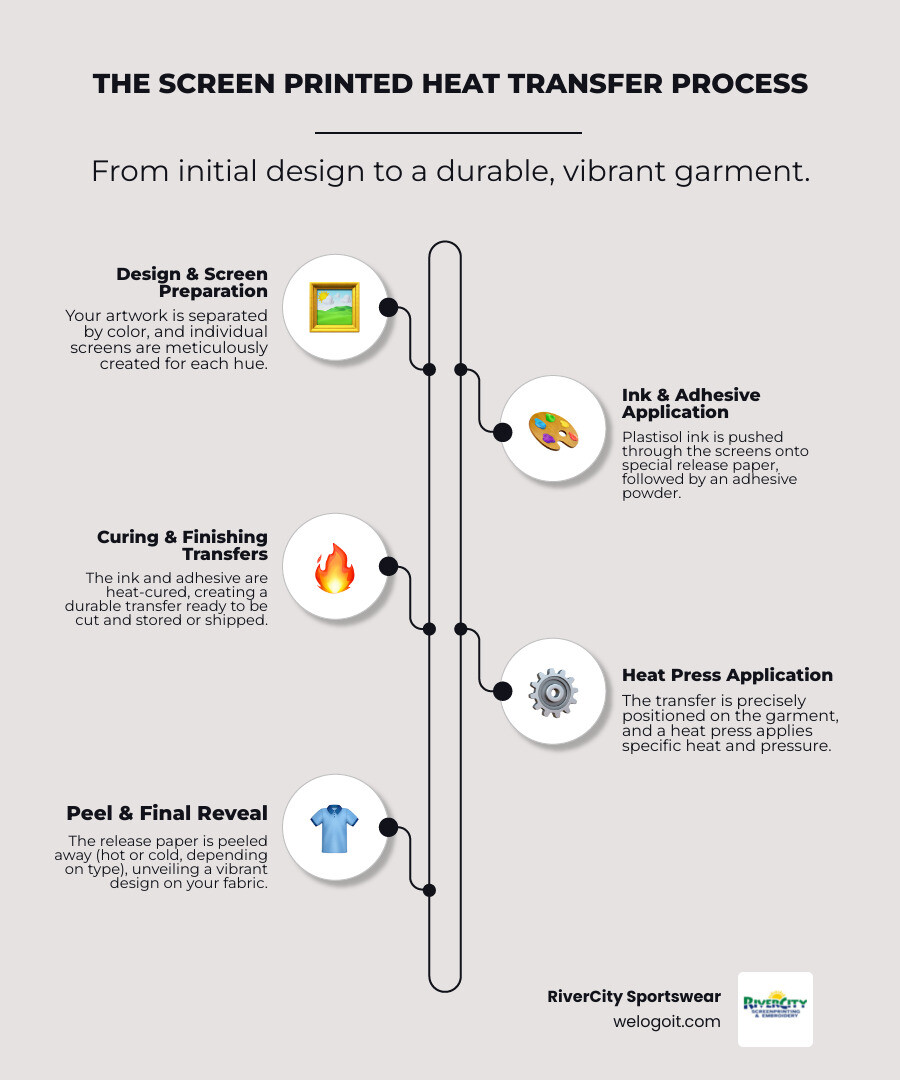

How They Work: From Screen to Shirt

The journey from a digital design to a ready-to-press transfer begins with screen creation. Each color in your design requires a separate screen. Next, liquid plastisol ink is pushed through these screens onto the release paper. A fine adhesive powder is then sprinkled over the wet ink and briefly heated, or “gelled,” to partially cure the ink and activate the adhesive.

The final step is application. You position the transfer on your garment and use a heat press to apply precise heat and pressure for a specific time (usually 12-15 seconds at around 310°F). This fully cures the ink, melts the adhesive, and bonds the design permanently to the fabric. Depending on the transfer type, you’ll either perform a “hot peel” (removing the paper immediately) or a “cold peel” (letting it cool first). To learn more, see our article on the Difference Between Screen Printing and Heat Press.

Advantages of Screen Printed Transfers

So, why choose screen printed heat transfers over other decoration methods? They offer a unique combination of quality, flexibility, and value that makes them a favorite for many of our clients throughout San Marcos, Austin, and Central Texas.

- Durability: Using robust plastisol inks, these transfers are built to last. They resist cracking, fading, and peeling, making them perfect for team uniforms or branded merchandise that needs to endure many washes.

- Vibrant Colors: Plastisol inks are highly opaque, producing rich, true-to-life colors that stand out on both light and dark fabrics.

- Soft Hand Feel: Modern transfers blend seamlessly with the fabric, creating a soft, comfortable feel that isn’t stiff or heavy.

- Cost-Effective: The setup costs are typically lower than direct screen printing for smaller runs, and when you order transfers in quantity, the per-unit price becomes very attractive.

- Versatility: Screen printed transfers can be applied to a vast array of fabrics and items that might be challenging for direct screen printing, such as hats, bags with awkward seams, or performance wear.

- On-Demand Printing: You can store transfers and apply them as needed. This eliminates the need for large inventory, reduces waste, and allows for quick fulfillment of orders. It’s an ideal solution for businesses with fluctuating needs. For more comprehensive benefits, explore The Advantages of Screen Printing.

Comparison with Other Methods

To truly appreciate the power of screen printed heat transfers, it helps to see how they stack up against other popular decoration methods. While direct screen printing and digital printing each have their strengths, transfers offer a unique blend of benefits.

| Feature | Screen Printed Heat Transfers | Direct Screen Printing –

| Cost (per transfer) | Typically lower for bulk transfers, varying from $0.15-$0.20 per transfer for simple designs. –

| Durability | Excellent. Long-lasting and resistant to cracking and fading. | Excellent. Very durable, with ink directly embedded in fabric. |

| Color Vibrancy | Excellent. Opaque plastisol inks produce bright, vivid colors on light and dark fabrics. | Excellent. Highly vibrant and accurate color reproduction. |

| Ideal Order Size | Small to medium runs, on-demand printing, or when inventory flexibility is needed. No minimums are common. | Medium to large runs (e.g., 6+ items minimum). Best value for larger quantities. |

| Versatility | Can be applied to a wide range of fabrics and items (hats, bags). | Best for flat, easily accessible surfaces. Can be limited by garment type. |

| Inventory | Transfers can be stored indefinitely, reducing inventory risk. | Requires direct printing onto garments, so garments must be stocked. |

| Application | Requires a heat press to apply, can be done in-house or by a third party. | Requires specialized screen printing equipment and expertise. |

Comparing this to digital printing methods like Direct-to-Garment (DTG) printing, screen printed heat transfers maintain their edge in durability and color vibrancy, especially for designs with fewer colors. DTG excels at highly detailed, full-color images with no minimums, but can sometimes lack the ‘pop’ and long-term washability of plastisol inks, and its cost per garment doesn’t decrease significantly with volume. For more on this, check out our article on Screen Printing vs Digital Printing for Your Project.

For us, the choice often comes down to your specific needs. If you’re looking for professional, durable, and vibrant results with flexibility in order size and inventory management, screen printed heat transfers are often the perfect solution.

Finding and Ordering Screen Printed Heat Transfers Near Me

When you’re searching for “screen printed heat transfers near me,” you’ll find both local print shops and online suppliers. A local provider, like us in Central Texas, offers personalized service, faster turnaround, and the ability to discuss your project in person. Online suppliers may offer a wide selection, but can lack that hands-on support.

What to Look for in a Provider

- Experience & Quality: Look for a provider with a proven track record. We’ve been screen printing since 1975, producing millions of high-quality, durable transfers. Always ask for samples to verify print quality.

- Customer Service & Design Support: A good partner will help you with your artwork. Our expert design team can help you refine your existing artwork, create new designs, or ensure your files are print-ready. For more tips, check out our guide on Finding a Great Screen Printer.

- Turnaround Time: Standard production is often 2-3 business days, but many providers, including us, offer rush services for quicker delivery.

The Ordering Process

Ordering custom transfers is a straightforward process:

- Artwork Submission: Provide your design in a high-resolution format. Vector files (.AI, .EPS, .SVG) are preferred for scalability, but high-resolution raster files (.JPG, .PNG) at 300 DPI also work. Our design team can help prepare your art for printing. Learn more about How to Prepare a Design for Screen Printing.

- Gang Sheets: To maximize value, you can place multiple designs or sizes on a single transfer sheet, known as a “gang sheet.” This optimizes space and reduces your per-transfer cost.

- Proof Approval: You’ll receive a digital mockup of your transfer to review and approve before we print, ensuring everything is perfect.

- Minimum Order Quantity: Screen printed transfers often have a small minimum order due to setup costs, though it’s typically much lower than for direct-to-garment printing. We offer flexible solutions for projects of all sizes.

At RiverCity Sportswear, we’re here to guide you every step of the way, making the process of ordering custom screen printed heat transfers near me as effortless as possible for our clients across San Marcos, Austin, and South Texas.

A Guide to Transfer Types, Application, and Costs

Understanding the different types of transfers, how to apply them, and the costs involved will help you make the best choice for your project.

The Application Process

Applying a screen printed transfer requires a heat press, which uses a combination of temperature, pressure, and time to bond the design to the fabric.

- Temperature: Typically between 300°F and 375°F.

- Pressure: Firm and even pressure is crucial.

- Dwell Time: Usually a quick 4 to 15 seconds.

Correctly balancing these three elements ensures a durable, professional-looking print. We always provide detailed instructions with our transfers. For more tips, see our guide on Tips for Ordering Screen Printed T-Shirts.

Common Types of Screen Printed Transfers

Different transfers suit different needs and fabrics. Here are some popular options:

- Goof Proof: The all-around workhorse, known for its versatility, durability, and soft feel.

- Hot Split Retro: Creates a vintage, slightly distressed look with a very soft finish.

- Elasti Prints: Ideal for stretchy performance wear like spandex or lycra, as it moves with the fabric without cracking.

- Puff Ink: Adds a 3D, textured effect to your design.

- Specialty Formulas: Options like glitter, glow-in-the-dark, and foil can add a unique, eye-catching element to your apparel. Learn more about Different Types of Ink Used in Screen Printing.

Popular Applications and Fabric Choices

The versatility of screen printed transfers makes them suitable for a wide range of items and materials. They work great on:

- Apparel: T-shirts, hoodies, and sweatshirts made from cotton, polyester, or blends.

- Accessories: Tote bags and hats, including those with difficult-to-print shapes.

- Branding: Custom neck labels for a professional, tag-free finish.

Our team can help you select the right transfer for your specific fabric and project. For more on fabric compatibility, check out our guide on the Best Fabrics for Screen Printing.

Understanding the Cost

Several factors influence the final price of your transfers:

- Number of Colors: Each color requires a separate screen, so simpler designs are more cost-effective.

- Order Quantity: The price per transfer decreases as the order size increases.

- Sheet Size: Using a “gang sheet” to fit multiple designs onto one sheet is a great way to save money.

- Specialty Inks: Unique effects like glitter or puff ink may have additional costs.

Screen printed transfers offer excellent value, especially for small-to-medium orders or when you need on-demand printing flexibility. For a deeper dive into pricing, our article on How the Cost of Your Screen Printing Order is Calculated offers more details.

Conclusion

We’ve journeyed through the vibrant world of screen printed heat transfers, solveing their mystery from the ink on a screen to the finished garment. We’ve seen how these versatile and durable transfers offer a smart, flexible solution for all your custom apparel needs, whether you’re a busy business in Austin, a school organization in San Marcos, or a community group across Central and South Texas.

To recap, the benefits are clear:

- Durability: They stand up to wear and tear, just like traditional screen printing.

- Vibrant Colors: Plastisol inks deliver eye-catching, opaque designs.

- Flexibility: Store transfers and apply them on demand, managing inventory with ease.

- Cost-Effectiveness: Especially for small to medium runs, offering professional results without breaking the bank.

- Versatility: Suitable for a wide array of fabrics and items, opening up endless possibilities.

Whether you’re looking to launch a new clothing line, create memorable team uniforms, or simply need custom t-shirts for an event, screen printed heat transfers provide high-quality results with incredible convenience. They empower businesses and hobbyists alike to create professional-grade custom apparel without the complexities of direct screen printing.

At RiverCity Sportswear, we’re more than just a printing company; we’re your partners in bringing your creative visions to life. With our personalized design support, exceptional customer service, and fast turnaround times, we make the process of getting screen printed heat transfers near me effortless and enjoyable. We’ve been serving our community with pride since 1975, and we’re committed to helping you succeed.

Ready to transform your ideas into stunning custom apparel? Don’t hesitate to reach out!