Custom Embroidered Patches: The Ultimate Guide for Brand Identity

Custom embroidered patches are fabric emblems with embroidered designs used to represent brands, commemorate events, or identify group membership. Here’s what you need to know:

- Starting cost: As low as $0.65 per patch for 1,000+ pieces

- Minimum order: Typically 25 pieces

- Turnaround time: 5-day rush available; standard shipping 9-13 business days

- Durability: Withstands up to 50 wash cycles when properly cared for

- Backing options: Iron-on, sew-on, Velcro, adhesive

Custom embroidered patches transform ordinary apparel and accessories into branded statements that capture attention and build recognition. Whether you’re outfitting a sports team, commemorating an event, or creating unique promotional items, these versatile fabric emblems offer an affordable way to make a lasting impression. With over two decades of industry experience, patch manufacturers have perfected the art of creating high-quality custom patches that combine durability with eye-catching design.

The beauty of custom embroidered patches lies in their versatility. They can be attached to uniforms, hats, bags, jackets, and countless other items. Organizations ranging from military units and scout troops to motorcycle clubs and corporate teams use them to foster unity and showcase identity. With modern production techniques, even intricate designs and small text can be rendered with impressive detail.

I’m Luke Sanders, CEO of RiverCity Screenprinting & Embroidery, where we’ve been creating premium custom embroidered patches for over 40 years, helping businesses and organizations establish memorable brand identities through quality promotional products. Our team of experts handles everything from design assistance to production and timely delivery.

Custom Embroidered Patches 101

Ever picked up a jacket or backpack with a beautiful design stitched onto it and wondered how it was made? That’s the magic of custom embroidered patches at work! These decorative fabric pieces bring logos, text, and images to life through precise thread stitching onto a base material.

When we create your patches at RiverCity Sportswear, we use specialized embroidery machines that carefully place each stitch exactly where it needs to go. The thread count—how many stitches fit into a square inch—is what gives your patch its level of detail and quality. Higher thread counts create more intricate, professional-looking designs that really catch the eye.

Want something that literally stands out? Our 3-D puff embroidery uses a special foam backing to create raised, three-dimensional designs. This technique makes your logos and text pop off the surface, creating visual interest that’s impossible to ignore. It’s perfect for team mascots or company logos that deserve that extra dimension!

One thing our customers love about custom embroidered patches is their incredible durability. With proper care, your patches can withstand up to 50 wash cycles without significant fading or fraying. That’s why they’re perfect for uniforms, work clothes, and sports gear that see heavy use day after day.

The possibilities for using custom embroidered patches are virtually endless. We’ve created patches for company uniforms, sports team jerseys, military insignia, scout achievement badges, motorcycle club emblems, event souvenirs, and even fashion accessories. Each one tells a story and creates a sense of identity and belonging.

For businesses placing bulk orders, the savings can be substantial. Our volume discounts can reach up to 74% for orders of 1,000 pieces or more compared to smaller quantities. That makes custom embroidered patches an incredibly cost-effective branding solution whether you’re outfitting a small team or a large organization.

History & Modern Benefits

The tradition of embroidered patches has deep historical roots, with military applications among the earliest and most notable uses. For centuries, armed forces worldwide have used patches to show rank, unit, achievements, and campaigns. This heritage continues today—every branch of the United States Armed Forces proudly displays custom embroidered patches on their uniforms.

Patches do much more than just identify. They’ve evolved into powerful branding tools that create instant recognition and foster community. When your team members wear your custom patch, they become walking ambassadors for your brand, spreading your message wherever they go.

From a marketing perspective, custom embroidered patches offer exceptional bang for your buck. Unlike promotional items that quickly end up in the trash, patches become part of garments people wear regularly. A single patch might be seen by hundreds or thousands of people throughout its lifetime, making it one of the most cost-effective marketing investments you can make.

Key Uses Across Industries

The versatility of custom embroidered patches makes them valuable across so many different settings:

Sports Teams and Athletic Clubs use patches to create unity and build team spirit. From little league to professional organizations, patches on uniforms, warm-up gear, and fan merchandise help teams stand out and build recognition.

Social Clubs and Organizations like motorcycle clubs, car enthusiasts, and hobby groups use patches as badges of membership and pride. These often become cherished collectibles that members display prominently.

Events and Commemorations deserve lasting mementos. Whether it’s a company milestone, music festival, or championship victory, custom patches preserve these special memories for years to come.

Scout Troops have perhaps the most iconic use of patches. Merit badges and troop identification patches have been motivating young people for generations, creating tangible rewards for achievement and growth.

Fashion Industry designers increasingly incorporate patches into their collections, either as permanent features or customizable elements. This trend has made patches a staple in contemporary streetwear and vintage-inspired fashion.

Corporate Uniforms transform from generic workwear to branded statements with the addition of patches. From retail staff to service technicians, patches help employees present a professional, cohesive appearance while reinforcing brand identity.

Here at RiverCity Sportswear, we’ve created custom embroidered patches for clients across Central and South Texas, from San Marcos to Austin, helping organizations in each of these sectors establish and maintain their visual identity with quality, craftsmanship, and care.

Patch Types & Materials at a Glance

When considering custom embroidered patches, it’s important to understand the various types available to ensure you select the option that best suits your needs:

The world of patches is surprisingly diverse! Embroidered patches are the classic choice that most people picture—featuring vibrant threads stitched onto fabric backing with a satisfying raised texture that catches both light and attention. These traditional favorites bring designs to life with dimension and character that’s perfect for logos and emblems where you want that authentic, premium look.

If you’re working with intricate details or tiny text, woven patches might be your new best friend. These smooth operators use thinner threads woven directly into the patch material (rather than sitting on top), creating a sleeker, more refined appearance. The result? Crisp, clean lines that can capture even the most delicate design elements with impressive precision.

For the outdoor enthusiasts and tactical gear lovers, PVC patches offer unbeatable durability. These tough customers laugh in the face of rain, mud, and rough handling. Their molded 3D appearance adds a modern, substantial feel that stands out from traditional fabric options. They’re essentially the “all-weather tires” of the patch world!

Want to add a touch of sophistication? Leather patches (available in both genuine and eco-friendly faux options) bring an unmistakable premium quality to any item. Whether debossed, engraved, or color-filled, they age beautifully and tell a story of craftsmanship and attention to detail.

Remember those classic varsity jackets? That distinctive fuzzy texture comes from chenille patches, which create a nostalgic, traditional appearance that’s perfect for school spirit wear and retro-inspired designs. They add both visual and tactile interest that begs to be touched.

For photorealistic designs or complex color gradients, dye-sublimated patches are truly magical. This special printing process infuses ink directly into the fabric, allowing for unlimited colors and incredibly detailed images that would be impossible with traditional embroidery.

The height of patch luxury comes in the form of bullion patches, handcrafted using metallic wire and threads. These stunners have adorned military uniforms and prestigious club jackets for generations, communicating tradition and excellence with their distinctive shimmer and weight.

For the environmentally conscious, many of today’s patch options come with eco-friendly thread choices made from recycled materials. At RiverCity Sportswear, we’re proud to offer sustainable options that look great while respecting our planet.

For more information about the history and evolution of embroidered patches, check out this informative article from Emblem Authority on the history of embroidered patches.

Embroidered vs. Woven Details

Choosing between embroidered and woven patches often comes down to understanding their unique characteristics and how they’ll complement your design:

Texture and Appearance: Embroidered patches have that classic, raised profile that creates natural shadows and highlights as light plays across the stitching. There’s something timelessly appealing about their dimensional quality—they literally stand out! Woven patches, meanwhile, offer a more subtle, integrated look with their flat profile. Think of it as the difference between a textured oil painting versus a smooth watercolor—both beautiful, but with distinct personalities.

Detail Capabilities: When your design includes tiny text or intricate linework, woven patches truly shine. Their construction allows for remarkably fine details—we’re talking text as small as 4 mm remaining perfectly legible. Embroidered patches excel at bold, impactful designs that command attention from across the room. They’re particularly effective with simpler logos that benefit from that extra dimension.

Coverage Percentage: Here’s a practical consideration that affects both appearance and wearability: embroidery coverage percentage. Designs with large solid areas require more thread, creating a stiffer patch. Woven patches naturally achieve full coverage since the design is built into the very structure of the patch. For embroidered options, incorporating some negative space can improve flexibility while maintaining visual impact—something our design team at RiverCity Sportswear can help you balance perfectly.

Still not sure which is right for your project? Check out our detailed comparison guide: Embroidered, Woven, or Dye Sublimated: Which Patch is Right for You?

Specialty Options (PVC, Leather & More)

Beyond the basics, specialty patch options open up exciting possibilities for specific applications and unique visual effects:

PVC/Rubber Patches have become the go-to choice for outdoor enthusiasts, tactical teams, and anyone whose gear faces challenging conditions. These three-dimensional wonders shrug off water, weather, and wear with impressive resilience. Modern manufacturing allows for precise color matching, glow-in-the-dark features, and even reflective elements for improved visibility.

Leather Patches speak a language of quality without saying a word. Whether crafted from genuine leather or high-quality alternatives, these patches add an unmistakable premium touch to any item. The beauty of leather patches lies in their change over time—they develop a rich patina with use, becoming more personal and distinctive.

Safety Certification matters, especially for patches destined for children’s items or uniform programs. Quality-focused manufacturers offer OEKO-TEX® certified materials, tested for over 100 harmful substances to ensure they’re safe for direct skin contact. This isn’t just a nice-to-have feature—for many applications, it’s essential peace of mind.

At RiverCity Sportswear, we understand that different projects have different requirements. That’s why we offer this full spectrum of patch options, helping you select the perfect material and construction technique for your specific needs, whether that’s weather resistance, premium appearance, or certified safety.

Designing & Ordering Like a Pro

Creating effective custom embroidered patches starts with proper artwork preparation. Think of the digitizing process as translating your vision into a language embroidery machines can understand—it’s the crucial bridge between your design idea and a beautiful finished patch.

Vector files (like SVG, AI, or EPS formats) are your best friends in this process. They can be scaled without losing quality, making the digitizing process more precise and ensuring your design translates beautifully to embroidery. Don’t have vector files? No worries—high-resolution images (300 DPI or higher) can also work well, though they might need a bit more attention from our digitizing team.

When it comes to colors, we know your brand identity matters. Our team uses specialized thread color charts to match your brand colors as closely as possible. While thread doesn’t always allow for exact Pantone matching (threads come in specific colors rather than being mixed like paint), our experienced digitizers have tricks up their sleeves—they can blend threads to achieve remarkably close approximations of your desired colors.

One thing I love about our process at RiverCity Sportswear is that we offer unlimited revisions of your digital proof before a single stitch is sewn. We want you to be completely happy with how your design will look when embroidered. For many clients, especially those ordering larger quantities, we can even provide sample photos of your actual patch before completing the full order. It’s like a dress rehearsal before the big show!

Our minimum order starts at just 25 patches, making custom embroidered patches accessible even for small teams or events. And if you’re ordering in bulk, you’ll see substantial savings—prices drop dramatically for orders of 1,000 or more patches. In a rush? No problem. Our 5-day rush production option has saved many last-minute events, while standard production typically takes 9-13 business days from approval to delivery.

Best of all, we include digitizing and setup in our pricing—what you see is what you get, with no surprise fees lurking around the corner.

Designing Custom Embroidered Patches: File & Color Tips

Let me share some insider tips to help you create custom embroidered patches that truly pop:

For artwork resolution, think “smartphone photo versus professional camera.” If you’re not using vector files, aim for at least 300 DPI (dots per inch) to ensure your design stays crisp and clear when converted to embroidery. Lower resolution images can end up looking like you’re viewing them through a foggy window—details get lost and edges become fuzzy.

When it comes to file formats, SVG, AI, and other vector formats are gold standard. These formats maintain clean lines and perfect shapes during the digitizing process. If you’re starting with a JPG or PNG, don’t worry—our team can work with these too, though they might need some digital TLC before they’re ready for the embroidery machine.

Color selection requires a bit of strategic thinking. While most custom embroidered patches can include up to 8 thread colors before affecting cost or quality, this isn’t as limiting as it might sound. Our designers are masters at creating striking designs within these constraints. Each color change requires the embroidery machine to stop and switch threads—like changing paintbrushes—so simpler color schemes often produce more efficient and better-looking results.

Want to add some extra flair? Consider specialty threads for unique effects. Standard embroidery thread gives a classic, satin-like finish, but metallic threads create shimmering gold, silver, or colored accents that catch the light beautifully. These are perfect for commemorative patches, awards, or any design where you want that touch of elegance that says “this is special.”

Even the backing material can play a role in your design. White, black, or colored twill backing can become part of the visual story, especially in areas that won’t receive embroidery coverage. It’s like choosing the right canvas before you start painting.

Our design team in San Marcos and Austin has helped thousands of clients optimize their artwork for embroidery. We love the collaborative process of ensuring your vision translates perfectly to the finished patch.

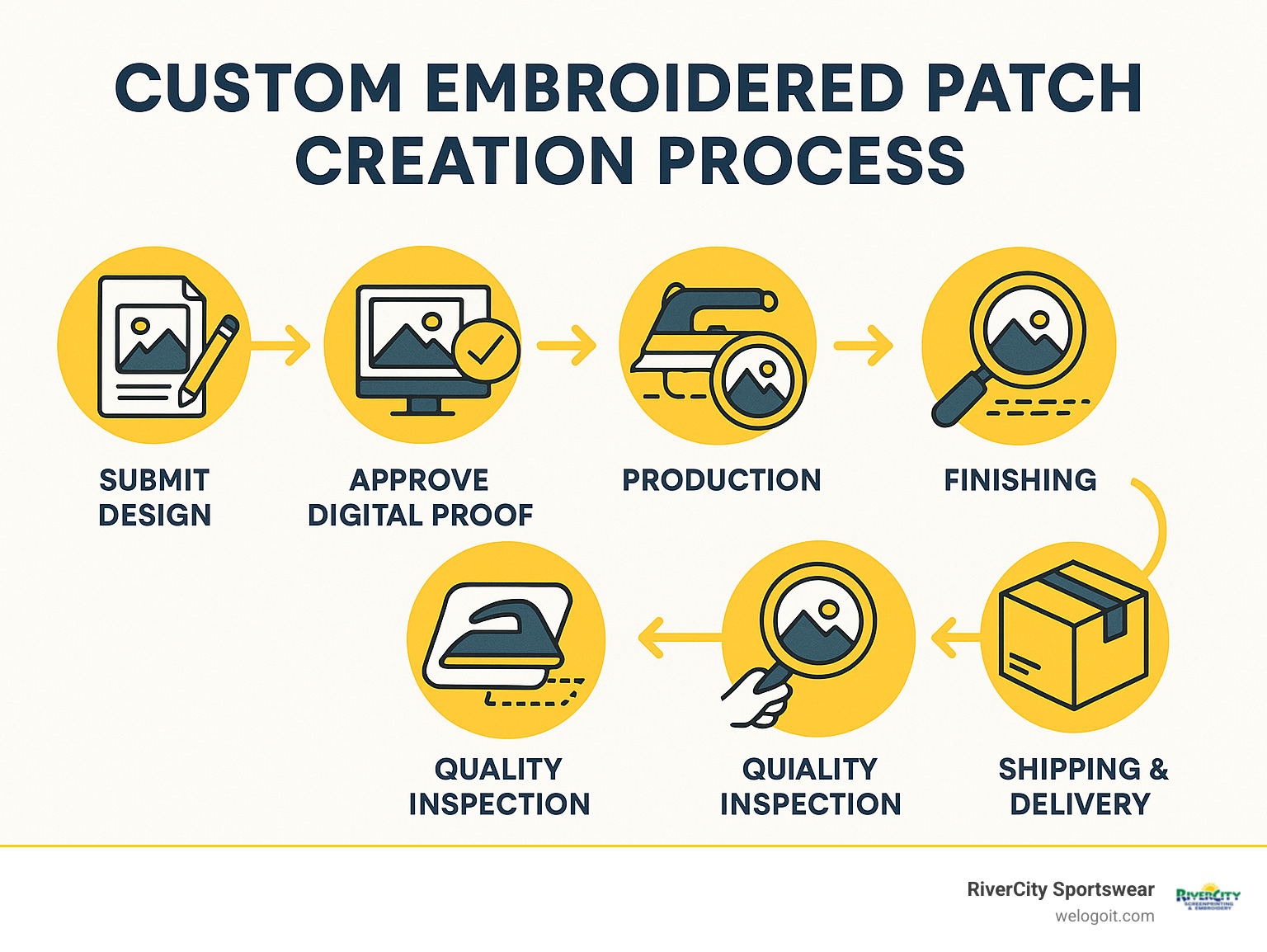

The Three-Step Ordering Process

Ordering custom embroidered patches is refreshingly simple—just three steps stand between your idea and the finished product:

1. Upload Your Artwork

Start by submitting your design through our online system or via email. Don’t have perfect artwork? No problem at all! Our creative team can help refine your existing design or even create something from scratch based on your ideas. We accept most common file formats, and our designers are experts at working with whatever you have. I’ve seen amazing patches emerge from initial concepts as simple as a rough sketch on a napkin!

2. Approve Your Digital Proof

Within just 1-2 business days after submitting your artwork, you’ll receive a digital proof showing how your design will look as an embroidered patch. This preview reveals the stitch pattern, colors, and overall appearance before production begins. Not quite right? We offer unlimited revisions at this stage—we want you to be thrilled with the result.

For complex designs or when you need absolute certainty, you can request a sample photo of your actual patch before approving full production. This extra step typically adds about 5 business days to the process but provides complete peace of mind about the final product. It’s particularly helpful for large orders or when precise color matching is crucial.

3. Receive Your Shipment

Once you’ve given the green light on your proof, our production team springs into action. Standard production takes approximately 7-10 business days, with shipping adding another 2-3 days for most locations throughout Texas. Need it faster? Our rush options have saved many events and promotions, with 5-day production possible for many orders.

Most orders include free standard shipping, and all patches come with our satisfaction guarantee. If there are any defects or issues with your order, we’ll replace them at no additional cost—that’s a promise.

Throughout this journey, you’ll have a dedicated account representative to answer questions and provide updates. At RiverCity Sportswear, we believe in real relationships with our clients—you’re never just an order number to us.

Pricing, MOQ & Turnaround

Understanding the dollars and cents of custom embroidered patches helps you plan your project effectively:

Our standard minimum order is 25 pieces. This threshold allows us to set up the embroidery machines efficiently while keeping your per-patch costs reasonable. Think of it like baking cookies—making just one or two requires almost the same setup time as making a dozen, so the per-cookie “cost” goes down significantly when you make more.

Patch pricing follows a tiered structure that rewards larger quantities. The price drops substantially as you order more patches—a 2-inch patch might cost around $2.50-$3.00 each at the 25-piece level but can drop to as little as $0.65 each when ordering 1,000 or more. That’s up to 74% savings! This dramatic price reduction makes larger orders extremely cost-effective, especially for organizations that can use the patches over time.

When it comes to timing, our standard production takes 7-10 business days, with shipping adding another 2-3 days for most locations in Central and South Texas. Need them for an upcoming event? Our 5-day rush production has saved countless last-minute situations (and probably a few careers along the way).

Several factors influence the final cost of your patches, and understanding them helps you make design choices that align with your budget:

Size naturally affects price—larger patches require more material and thread. Complexity plays a role too, as intricate designs with many details take longer to digitize and embroider. The number of thread colors impacts production time, as each color change requires machine adjustments. Backing types like Velcro add to the base cost, while special border styles beyond the standard merrowed edge might affect pricing. Special effects like 3D puff embroidery or metallic threads typically add a small premium, and rush production usually comes with additional fees for expedited service.

At RiverCity Sportswear, we believe in transparent pricing with no hidden fees or surprises. Our quotes include digitizing, setup, and standard backing options, so you’ll know exactly what to expect before placing your order. We’ve been helping organizations throughout Texas create memorable custom embroidered patches for decades, and we’d love to do the same for you.

Applying & Caring for Patches + FAQs

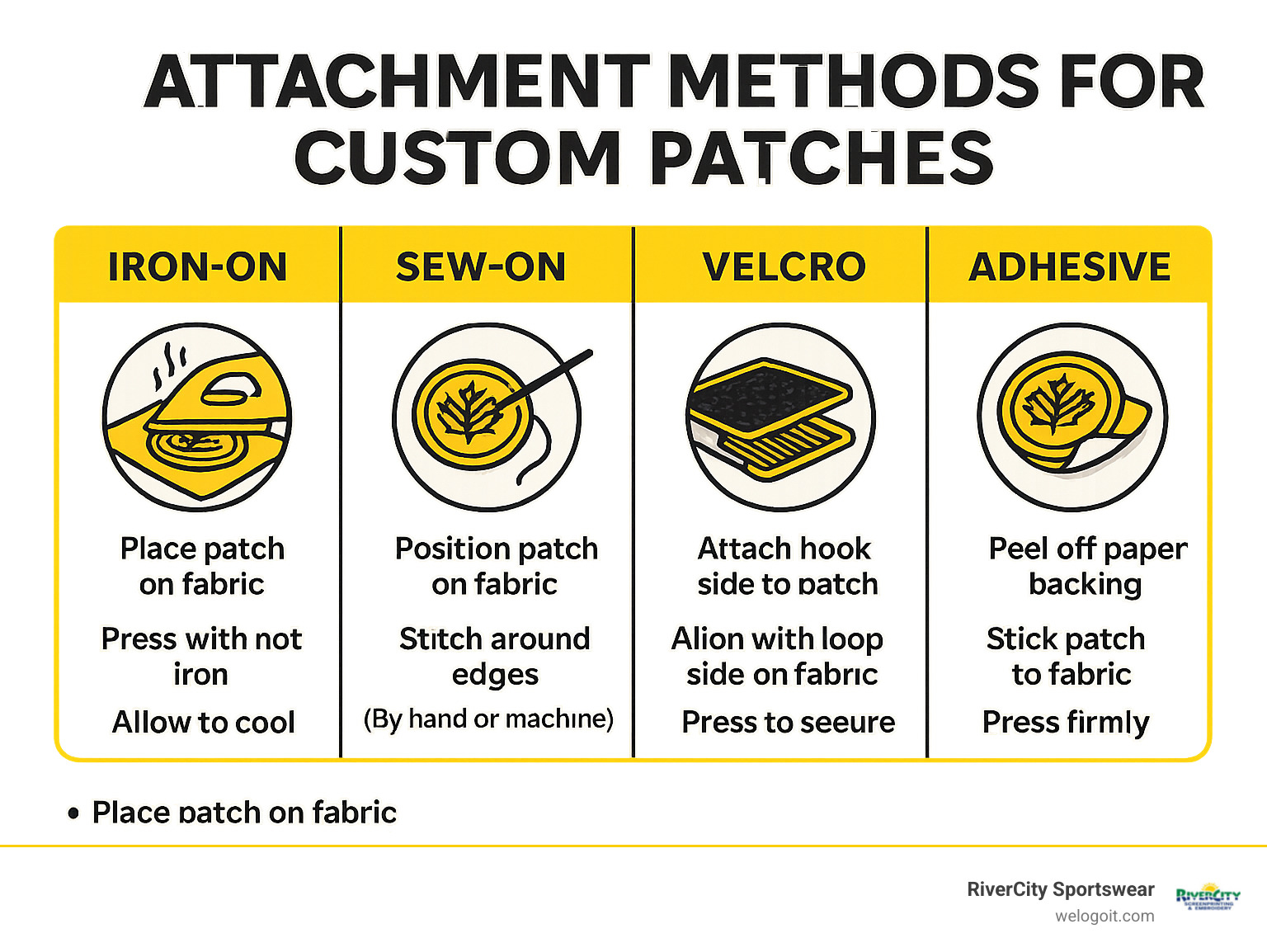

You’ve received your beautiful custom embroidered patches – now what? Let’s talk about how to attach them properly and keep them looking great for years to come. The right application method depends on both your patches and what you’re attaching them to.

Iron-on patches offer convenience with their heat-activated adhesive backing. When heated, this adhesive melts and creates a bond with your fabric. It’s perfect for home application when you don’t have sewing skills or patience for hand-stitching. Just remember that while quick and easy, this method might not hold up through dozens of wash cycles or on heavily used items.

For maximum durability, nothing beats sew-on patches. Whether done by hand with needle and thread or with a sewing machine, this traditional method creates the strongest attachment. Yes, it takes more time, but your patches will stay put through countless washes and wears.

Need flexibility? Velcro® backing (hook-and-loop) is your friend. This option is fantastic for tactical gear, uniforms that need frequent laundering, or situations where you might want to swap patches occasionally. Many of our military and law enforcement customers prefer this option for its practicality.

Some situations call for adhesive backing – the simple peel-and-stick approach. While not as durable as other methods, it’s perfect for temporary applications or items that won’t see much washing.

For professional results, nothing beats a heat press machine. The consistent temperature and pressure create the strongest possible bond for iron-on patches. Here at RiverCity Sportswear, we’re happy to apply your patches using our professional equipment for a small fee – just ask!

With proper care, your custom embroidered patches can last through up to 50 wash cycles while still looking fantastic. The secret? Turn garments inside-out, use cold water on a gentle cycle, and skip the harsh detergents and bleach. When possible, air dry instead of using high heat in the dryer, and your patches will thank you with years of service.

Applying Custom Embroidered Patches Correctly

Let’s get those patches attached properly! For professional-looking results, follow these tried-and-true techniques:

If you’re using a heat press (the gold standard for iron-on patches):

- Set your heat press to 305 °F (150 °C) – temperature matters!

- Position your patch exactly where you want it, adhesive side down.

- Place a thin cloth or Teflon sheet over the patch to protect both it and your garment.

- Apply firm, even pressure for 12-15 seconds.

- Let everything cool completely before handling or washing.

Using a regular household iron? No problem:

- Crank that iron to its highest setting (usually labeled “cotton” or “linen”).

- Place your patch adhesive-side down on your item.

- Cover with a thin cloth to protect the patch.

- Press down firmly for 30-45 seconds, applying as much pressure as you can.

- Check the edge of the patch to make sure the adhesive has melted and bonded.

- Allow to cool completely before handling.

Here’s a pro tip from our decades of experience: For patches that will see heavy use, consider the “belt and suspenders” approach – apply with iron-on adhesive first, then add a few strategic stitches around the edge. You’ll get the convenience of iron-on with the security of sewing.

Care & Longevity Tips

Want your custom embroidered patches to stay vibrant and secure for the long haul? Follow these simple care guidelines:

Always wash in cold water on a gentle cycle. Hot water is the enemy of both thread integrity and color vibrancy. Turn garments inside-out before washing to minimize direct abrasion on the patch surface.

Skip the bleach and harsh detergents – they can damage threads and break down adhesives over time. Whenever possible, air dry your patched items or use the lowest heat setting on your dryer. High heat is particularly tough on patches with iron-on backing.

Avoid dry cleaning unless you’ve confirmed your patches can handle it. The chemicals used in dry cleaning can be rough on embroidery threads and backings.

If you notice an iron-on patch starting to lift at the edges after multiple washes, don’t wait for it to come off completely. A few reinforcement stitches can extend its life significantly.

Store any unused patches flat in a cool, dry place away from direct sunlight to prevent color fading or adhesive deterioration before you even use them.

For patches on work uniforms or outdoor gear that face tough conditions, make it a habit to periodically check the edges for any signs of lifting. A little preventive maintenance goes a long way!

Frequently Asked Questions about Custom Embroidered Patches

What backing should I choose?

This is one of our most common questions, and the answer depends on how you’ll use your patches:

Iron-on backing works wonderfully for one-time application to fabric items that won’t see extreme use. It’s perfect for cotton, polyester, and poly-cotton blends, making it ideal for most standard apparel. The convenience factor is high, especially for home application.

Sew-on backing is the workhorse option. It provides the most durable attachment and works on virtually any material – even leather, heavy canvas, and other materials that heat-activated adhesives can’t penetrate. Choose this option for items that will face frequent washing or rough conditions.

Velcro® backing shines when patches need to be removed and reattached regularly. It’s the go-to choice for military, tactical, and many corporate applications where uniform patches might need to be changed or removed for cleaning.

Adhesive backing offers peel-and-stick convenience for temporary applications or materials that can’t be sewn or heat-pressed. While not washable, it’s perfect for quick application to items like temporary signage or non-fabric surfaces.

Here at RiverCity Sportswear, we’re happy to help you select the right backing based on your specific needs – just tell us how you’ll be using your patches, and we’ll guide you to the best option.

How many colors can I include?

Most custom embroidered patches can include up to 8 thread colors before affecting cost or quality. This limitation exists because each color change requires the embroidery machine to stop and switch threads, which increases production time and complexity.

If your design requires more than 8 colors or includes photorealistic images, consider dye-sublimated patches instead. These can reproduce unlimited colors, gradients, and complex images with amazing clarity. Alternatively, our skilled digitizers can sometimes create the illusion of additional colors by strategically placing threads to create blended effects – a little embroidery magic!

We match thread colors to your specifications using industry-standard thread charts. While exact Pantone matching isn’t always possible with embroidery thread, our experienced team can achieve very close approximations of most brand colors. Your logo’s colors are important to us, and we’ll work hard to get them right.

What is the typical turnaround time?

For standard orders, you can expect production to take 7-10 business days from proof approval to shipping. With standard shipping added, you’ll typically receive your custom embroidered patches within 9-13 business days total.

Need them faster? We understand that sometimes time is of the essence. That’s why we offer rush production options:

5-day rush production is available for most standard patch types. If you need sample photos before full production, add approximately 5 business days to the timeline. Our digital proofs are usually provided within 1-2 business days of artwork submission, so you can quickly see how your design will look.

Several factors can affect turnaround time, including order quantity, design complexity, and special features like 3D embroidery or custom backings. For events or promotions with fixed deadlines, we recommend placing your order at least 3-4 weeks in advance. This allows time for design adjustments and production without rush fees.

At RiverCity Sportswear, we understand that timing is often critical, especially for events in the San Marcos, Austin, and greater Central Texas region. We’re committed to meeting your deadlines and will work with you to find solutions even for last-minute needs. After all, we’ve been helping Texas businesses look their best for over 40 years – we know a thing or two about coming through in a pinch!

Conclusion

Custom embroidered patches have this wonderful way of bridging the old and new—combining centuries of tradition with modern branding power. There’s something genuinely special about these tactile emblems that digital alternatives just can’t match. Whether you’re drawn to the classic raised texture of traditional embroidery, the sleek precision of woven patches, or the dimensional impact of PVC options, you’ll find a style that perfectly captures your vision.

Creating custom patches has become remarkably accessible over the years. With minimums starting at just 25 pieces, even small teams and events can enjoy professional-quality patches. And for larger organizations? The savings are substantial—up to 74% off when ordering in bulk. What’s more, these little fabric ambassadors keep working for you through up to 50 wash cycles, continuing to represent your brand long after most promotional items have been forgotten.

Here at RiverCity Sportswear, we take genuine pride in being your local partner for patch production throughout San Marcos, Austin, and all of Central and South Texas. Our team brings decades of hands-on experience to every project, combining time-tested techniques with modern production methods to create patches that truly stand out. We’re not just making patches—we’re helping you tell your story.

Whether you’re outfitting a youth sports team for their championship season, creating meaningful mementos for a special event, or building consistent branding across your entire organization, we’re right beside you at every step. From those initial design conversations to the moment your patches arrive, our focus is on making the process smooth, enjoyable, and stress-free.

Ready to turn your ideas into patches people will wear with pride? We’d love to help! Reach out today for a friendly chat and a no-obligation quote. With RiverCity Sportswear, you’re not just ordering patches—you’re creating lasting symbols of identity that will represent your brand beautifully for years to come. Learn more about our embroidery services and let’s start creating something special together.