What is Custom Screen Printing and Why Does It Matter?

Custom screen printing is a proven printing technique that transfers ink through a mesh screen onto fabric or other materials using a stencil and squeegee. Here’s what you need to know:

- Best for bulk orders (typically 25+ pieces) where per-unit costs drop significantly

- Creates vibrant, durable prints that last through dozens of washes without fading

- Works on apparel and promotional items including t-shirts, hoodies, tote bags, hats, and more

- Ideal for designs with 1-8 solid colors rather than complex photorealistic images

- Standard turnaround is 5-10 business days, with rush services available

Also known as silk screening, this method has been around since ancient times but became a commercial printing staple in the early 20th century. The process uses a fine mesh screen stretched over a frame. A stencil blocks certain areas while ink passes through open mesh sections onto the garment below. Each color in your design requires a separate screen, which is why custom screen printing shines for bold, simple designs rather than full-color photographs.

This versatility makes screen printing the go-to choice for event organizers planning team uniforms, businesses ordering company apparel, or anyone needing promotional products that actually last. Unlike cheaper methods that crack or peel after a few washes, properly cured screen-printed designs bond directly with fabric fibers.

I’m Luke Sanders, CEO of RiverCity Screenprinting & Embroidery, where we’ve been perfecting custom screen printing for over 40 years in San Marcos and Austin, Texas. Our team has printed millions of garments for businesses, events, and brands across Central and South Texas.

Why Choose Screen Printing? The Benefits of a Timeless Technique

When you’re deciding how to put your logo or design on shirts, bags, or other gear, custom screen printing keeps coming out on top. We recommend it all the time here at RiverCity Sportswear, especially when our clients in San Marcos and Austin need quality that lasts and prices that make sense for larger orders.

The biggest reason? Durability. Screen-printed designs don’t just sit on top of the fabric—the ink actually bonds with the fibers themselves. This means your logo or artwork will survive dozens of washes without fading, cracking, or peeling. We’ve had customers tell us their screen-printed shirts still look great years later, long after they’ve worn them to death. When you’re investing in uniforms or promotional items, that kind of longevity matters. Your brand keeps making an impression wash after wash.

Then there’s the color vibrancy. Screen printing creates bold, rich colors that really pop, especially on dark garments. Because the ink goes on thicker than other methods, you don’t get that washed-out look where the shirt color shows through your design. Your whites stay white. Your reds stay fire-engine bright. And your brand colors look exactly how they should—no compromises.

Here’s where custom screen printing really shines for businesses and organizations: it’s incredibly cost-effective for bulk orders. Yes, there’s an upfront cost to create the screens for each color in your design. But once those screens are made, printing additional items becomes very affordable. The more you order, the lower your per-piece price drops. For team uniforms, event t-shirts, or company giveaways where you need 25 pieces or more, screen printing gives you the best bang for your buck.

And don’t think screen printing only works on t-shirts. It’s remarkably versatile across cotton and cotton-blend fabrics. We print on hoodies, polos, tank tops, tote bags, and more—all with the same durable, vibrant results. This means you can keep your branding consistent across all your promotional products.

Here’s how screen printing stacks up against other decoration methods:

| Feature | Screen Printing | Other Methods |

|---|---|---|

| Best For | Bulk orders (25+ pieces) | Smaller quantities or complex images |

| Durability | Excellent—ink bonds with fabric, withstands repeated washing | Varies—some methods crack or fade faster |

| Color Vibrancy | Outstanding, especially on dark garments with full opacity | Can appear muted on dark fabrics |

| Cost Per Item | Lowest for large runs after setup costs are covered | Higher per-item cost for bulk orders |

| Wash-Fastness | Superior—properly cured ink lasts for years | Moderate—may show wear sooner |

When is Screen Printing the Best Choice?

Screen printing really is the perfect fit for certain situations. If you’re ordering team uniforms, you need something that can handle sweat, frequent washing, and rough use—screen printing delivers that toughness game after game. Planning an event like a charity run or music festival in Austin? Screen printing lets you produce hundreds of shirts or tote bags that people will actually keep and wear long after the event ends.

For company apparel, screen printing gives your employees professional-looking branded shirts that hold up to daily wear. And when you’re running brand promotions, those vibrant colors we talked about? They make your logo impossible to ignore.

The sweet spot for screen printing is large quantity orders—typically 25 pieces or more. That’s when the economics really work in your favor. If your design uses a limited number of colors (usually one to eight), screen printing will give you crisp, clean results with excellent color separation. And when you need extreme durability—think work uniforms that get washed constantly or merchandise that becomes someone’s favorite shirt—screen printing outlasts everything else.

Limitations and When to Consider Alternatives

We believe in being straight with our clients about what works best for their specific project. While custom screen printing is fantastic for many situations, it’s not always the perfect solution.

If your design has complex artwork with many colors—say, nine or more—screen printing gets expensive fast. Each color needs its own screen, which adds to both setup costs and production time. Similarly, photorealistic images with subtle gradients and detailed shading don’t translate well to screen printing. The technique works best with bold, solid colors rather than photo-quality detail.

For small orders or one-offs, the setup costs make screen printing impractical. If you only need one or two shirts, paying for screen creation doesn’t make financial sense. The same goes for single items—the per-piece price would be way too high.

And remember: the cost per color increases with each additional shade in your design. If your artwork features a rainbow of colors, you might want to simplify the design or talk with us about whether another method would serve you better.

We’re always here to walk you through these decisions and find the right solution for your project. Sometimes that means tweaking a design to work better with screen printing. Other times, we might suggest a different approach altogether. Either way, you’ll get the best results for your budget and vision.

The World of Custom Screen Printing: Inks, Products, and Possibilities

The beauty of custom screen printing lies not just in its durability and vibrant colors, but also in the incredible variety of products it can transform. Over our 40 years serving Austin and San Marcos, we’ve printed everything from simple t-shirts to elaborate promotional campaigns that helped local businesses grow their brands.

When it comes to apparel, custom screen printing truly shines. We print on t-shirts every single day—they’re the backbone of team uniforms, event merchandise, and brand giveaways. But that’s just the beginning. Hoodies and sweatshirts provide a cozy canvas perfect for fall festivals or corporate retreats. Polos offer a professional look that works beautifully for restaurant staff or sales teams who need to look sharp while staying comfortable. And tank tops are ideal for summer runs, beach events, or athletic teams practicing under the Texas sun.

Beyond clothing, we print on promotional products that help your brand travel further. Tote bags have become incredibly popular as eco-friendly alternatives to plastic bags, and they turn every trip to the grocery store into a branding opportunity. Koozies keep drinks cold at parties and outdoor events while keeping your logo front and center. We also print on banners for trade shows and storefronts, posters for event promotion, and various other items that help spread your message.

Successful brands understand that quality screen printing builds lasting impressions. Companies like Paranoid have built their entire streetwear presence on the consistent quality and vibrant colors that screen printing delivers. That same level of quality is available to businesses right here in Central Texas.

Understanding Screen Printing Inks

The ink we choose for your project dramatically affects how your finished product looks, feels, and lasts through years of wear. We work with three main ink types, each with its own personality and purpose.

Plastisol ink is our workhorse—the ink we reach for most often. It sits on top of the fabric rather than soaking in, which creates incredibly vibrant, opaque colors that pop even on dark garments. Plastisol is remarkably durable, often outlasting the garment itself. We’ve seen shirts printed 15 years ago that still look crisp and fresh. This ink doesn’t dry until we cure it with heat, which gives us excellent control during printing and results in designs that resist cracking and fading. When you need perfect Pantone color matching for brand consistency, plastisol delivers every time.

Water-based ink takes a different approach. Instead of sitting on top, it absorbs into the fabric fibers, becoming part of the shirt itself. The result is an incredibly soft feel that gets even softer after the first wash. You can barely feel the print at all. Water-based inks work beautifully on lighter-colored garments and create that vintage, lived-in look that’s so popular right now. They’re also considered more environmentally friendly, which matters to brands building sustainable practices.

Discharge ink is water-based ink’s sophisticated cousin. It actually removes the dye from the fabric and replaces it with ink color, creating a “no-feel” print that breathes like the original fabric. This technique works best on dark 100% cotton garments, producing that soft, vintage aesthetic without any heavy ink layer. There can be a 5-10% color variance with Pantone matching, but the trade-off is that impossibly soft feel.

When clients ask about environmental considerations, we’re honest: water-based and discharge inks generally have a lighter environmental footprint than plastisol. We’re happy to discuss these options and help you choose the ink that aligns with both your brand values and your design goals.

Lift Your Design with Specialty Inks

Sometimes a standard print just isn’t enough. That’s where specialty inks come in—they’re the secret ingredients that transform a good design into something people can’t stop touching and talking about. We offer several creative options that add visual and tactile excitement to your custom screen printing projects.

Puff ink creates a raised, three-dimensional effect that literally puffs up off the garment when we cure it. Run your hand over it and you’ll feel the difference. It adds playful texture and makes designs pop in a way that flat ink simply can’t match.

Want some sparkle? Glitter and metallic inks bring the shine. Glitter inks contain tiny reflective flakes that catch the light from every angle, while metallic inks deliver a smooth, shimmering finish that looks luxurious and feels special. They’re perfect for adding glamour to event shirts or making your brand stand out at trade shows.

Foil overlays take metallic effects to the next level. We print a special adhesive, then heat-press metallic foil sheets onto it. The result is a brilliant, mirror-like finish that reflects light like jewelry. It’s eye-catching and premium-looking—perfect for high-end merchandise or VIP event shirts.

Glow-in-the-dark ink is pure fun. It absorbs light during the day, then glows brightly when the lights go out. We’ve used it for nighttime races, Halloween events, and concert merchandise. Kids especially love it, but honestly, adults can’t resist touching it either.

Finally, reflective ink serves both style and function. Tiny glass beads in the ink reflect light just like road signs, making your design visible from far away. It’s essential for safety gear but has also become popular in streetwear for that unique, urban aesthetic.

These specialty options can lift your project from ordinary to unforgettable. Whether you’re planning team uniforms, promotional products, or event merchandise here in Austin, let’s talk about how specialty inks can make your vision shine.

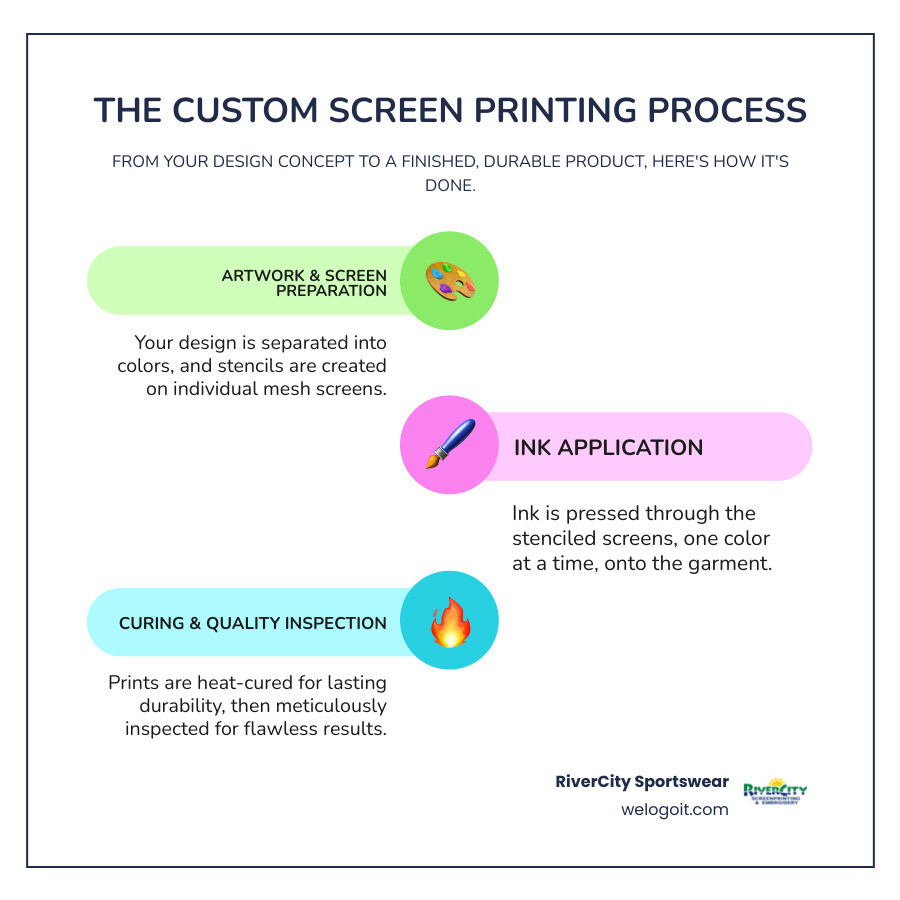

From Concept to Creation: The Screen Printing Process Explained

Bringing your vision to life through custom screen printing is a detailed process that we’ve refined over decades at RiverCity Sportswear. Our goal is to make every project smooth and stress-free, whether you’re ordering team uniforms in San Marcos or promotional items for an Austin event.

Let’s talk timing first. Our standard turnaround time is typically 5-10 business days from the moment everything is finalized—that means your artwork is approved, garment sizes and colors are confirmed, and we’ve received your deposit. We know life doesn’t always follow a neat schedule, though. When you’re in a pinch, we offer rush services to help you meet tight deadlines. These expedited orders may come with a surcharge, but we’ll work with you to find a solution that fits your timeline and budget.

The garments you choose play a bigger role than you might think. Fabric type and color significantly impact how your design turns out. Cotton and cotton-blend garments are our favorites because the ink bonds beautifully with these materials, creating vibrant, lasting prints. Not every fabric works well with screen printing, so we’ll always guide you toward the best options for your specific design.

Here’s something important about dark garments: to keep your colors bright and true, we typically print an underbase first. Think of it as a primer coat—we lay down a layer of white ink before adding your actual design colors. This prevents the dark fabric from swallowing your design and keeps everything looking crisp and vibrant. We include this flash printing on dark garments as standard practice because we’re committed to delivering superior quality every time.

Preparing Your Artwork for Flawless Custom Screen Printing

Great screen printing starts with great artwork. This is where the magic begins, and we’re here to help you every step of the way.

We work best with vector files—specifically AI (Adobe Illustrator) or EPS (Encapsulated PostScript) formats. These files are perfect because we can scale them to any size without losing quality. Your logo will look just as sharp on a small polo as it does on a large banner. Don’t have a vector file? No problem. We can often convert what you have, or our design team can help create something from scratch.

If your design includes photos or other raster images, we need them at 300 DPI (dots per inch) at the actual print size. This prevents that frustrating pixelation that makes designs look fuzzy or blurry. Sharp, clear images make all the difference.

Color separation is where screen printing gets technical, but we handle all of this behind the scenes. Each color in your design needs its own screen, so we separate your artwork into individual color layers. This is why screen printing works best with designs that have a limited number of distinct colors—each one requires its own setup.

Brand consistency matters, especially if you’re a business ordering company apparel or promotional products. That’s why we use the Pantone Matching System (PMS). When you specify your brand’s Pantone colors (Coated Pantones work best), we can match them with 100% accuracy using plastisol inks. Your logo will look identical across every shirt, hoodie, and tote bag we print.

Before we start production, you’ll receive digital mockups showing exactly how your design will look on the chosen garment. We’ll show you the placement, colors, and overall appearance. This design approval process is your chance to make any tweaks or adjustments. We don’t print a single shirt until you’re completely happy with what you see. Whether you’re starting with a napkin sketch or a polished vector file, we’ll work together to make your vision a reality.

Caring for Your Screen-Printed Items

Once your custom screen-printed items arrive, a little care will keep them looking fresh for years. We want your investment to last, so here’s how to protect those vibrant prints.

When it’s time to wash your screen-printed garments, always turn them inside-out and use cold water. This simple step protects the print from rubbing against other clothes in the wash and helps prevent fading. It’s the single best thing you can do to extend the life of your design.

For drying, tumble dry on low heat or hang dry whenever possible. High heat is the enemy of screen-printed designs. While our inks are incredibly durable when properly cured, excessive heat from a dryer can cause premature cracking or fading over time.

A few more tips to avoid damage: skip the bleach entirely, as harsh chemicals can break down both the ink and fabric. If you need to iron your garment, never iron directly on the print. Turn the item inside-out first, or place a cloth between the iron and the design. This prevents direct heat from damaging the ink.

Follow these straightforward guidelines, and your screen-printed apparel will continue promoting your team, event, or business for years to come. We’ve printed items that have lasted through hundreds of washes—proper care makes all the difference.

Frequently Asked Questions about Custom Screen Printing

We love talking shop about custom screen printing! Over the years, we’ve helped thousands of clients in San Marcos and Austin bring their ideas to life, and we’ve noticed some questions come up again and again. Let’s tackle the big ones:

How durable is a screen-printed design?

This is probably the question we hear most often, and we’re always happy to share the good news: custom screen printing creates incredibly durable designs. When we cure your prints properly, the ink doesn’t just sit on top of the fabric—it actually bonds with the fibers themselves. This deep bonding is what makes screen printing so resilient.

Your screen-printed shirts, hoodies, or tote bags will stand up to dozens and dozens of washes without the design cracking, peeling, or fading. We’ve had customers tell us their favorite screen-printed shirts are still going strong after five years of regular wear and washing! The key to this longevity is proper curing during production, which we handle with precision, and following the care instructions we provide. Washing your items inside-out in cold water and tumble drying on low will keep those prints looking sharp for years to come.

What is the minimum order for screen printing?

We get this question all the time, especially from folks planning their first event or starting a new business. The honest answer is that custom screen printing works best when you’re ordering in bulk. Our typical minimum order is around 25 to 34 units per design, though this can vary depending on your specific project.

Why the minimum? It comes down to economics and the nature of the process. Creating the screens for each color in your design requires an initial setup investment in materials and labor. When you’re printing 100 shirts, that setup cost gets spread across all those items, making each shirt very affordable. But if you only need five shirts, those same setup costs would make each one pretty expensive.

Think of it like baking cookies—it takes the same effort to preheat the oven whether you’re making one dozen or five dozen, so making more at once just makes sense. For smaller quantities or one-off items, we’re happy to discuss alternative printing methods that might be more cost-effective for your needs.

Can you print my complex, multi-color photograph?

Short answer: technically yes, but it’s probably not the best choice. Custom screen printing has many strengths, but reproducing your family vacation photo or a full-color sunset isn’t one of them.

Here’s why: screen printing is designed for bold graphics with distinct, solid colors. Each color in your design needs its own screen, and photorealistic images can contain dozens or even hundreds of subtle color variations. Trying to replicate all those colors with screen printing would require numerous screens, making the setup incredibly expensive and the production process complex.

Where screen printing truly shines is with designs that have one to eight distinct spot colors—think company logos, team mascots, or bold graphic designs. These come out crisp, vibrant, and beautiful. For photorealistic images or designs with intricate color blending and gradients, we’ll typically recommend exploring other printing options that are specifically designed for that level of detail. Our team is always here to review your specific design and guide you toward the method that will give you the best results for your budget. Sometimes the best answer is simplifying a complex design to work beautifully with screen printing, and we’re happy to help with that too!

Conclusion: Bring Your Vision to Life in Austin

We’ve taken quite a journey through custom screen printing, and if there’s one thing we hope you’ve finded, it’s that this timeless technique remains unbeatable for creating apparel and promotional products that truly last. The durability alone speaks volumes—designs that bond with fabric fibers and withstand dozens of washes without fading or cracking. Add to that the brilliant color vibrancy that makes your brand pop, especially on dark garments, and you’ve got a winning combination.

What makes custom screen printing particularly appealing is its cost-effectiveness for groups and businesses. Whether you’re ordering 25 pieces or 2,500, the economics work in your favor as your quantity increases. That’s why so many local businesses, schools, sports teams, and event organizers throughout Austin and San Marcos turn to screen printing for their apparel needs.

The possibilities for apparel, events, and branding are truly endless. Team uniforms that stand up to athletic wear and tear. Event merchandise that attendees will actually want to keep and wear. Company apparel that makes your staff look professional and unified. Brand promotions that get your message out there in a format people love. And with specialty inks like puff, glitter, and metallic finishes, you can transform a simple design into something memorable and unique.

Here at RiverCity Sportswear, we bring over 40 years of local expertise right here in Austin, Texas. We know the Central and South Texas market, we understand what works, and we’re committed to providing the fast turnaround and personalized design support that sets us apart. Our team has printed millions of garments, and we treat every order—whether it’s your first 25 shirts or your tenth thousand—with the same attention to quality and detail.

We don’t just print shirts; we help bring your vision to life. From that initial conversation about your idea to the moment you open the box and see your finished products, we’re with you every step of the way. Need help with artwork? We’ve got you covered. Wondering which ink type will work best for your design? Let’s talk it through. Tight deadline? We offer rush services to help you meet it.

Ready to get started? Explore our custom promotional products and get a quote today. We can’t wait to help you create something amazing that you’ll be proud to wear, share, and show off. Your ideas deserve to be printed right—let’s make it happen together.