Why High Volume Screen Printing Is the Smart Choice for Bulk Orders

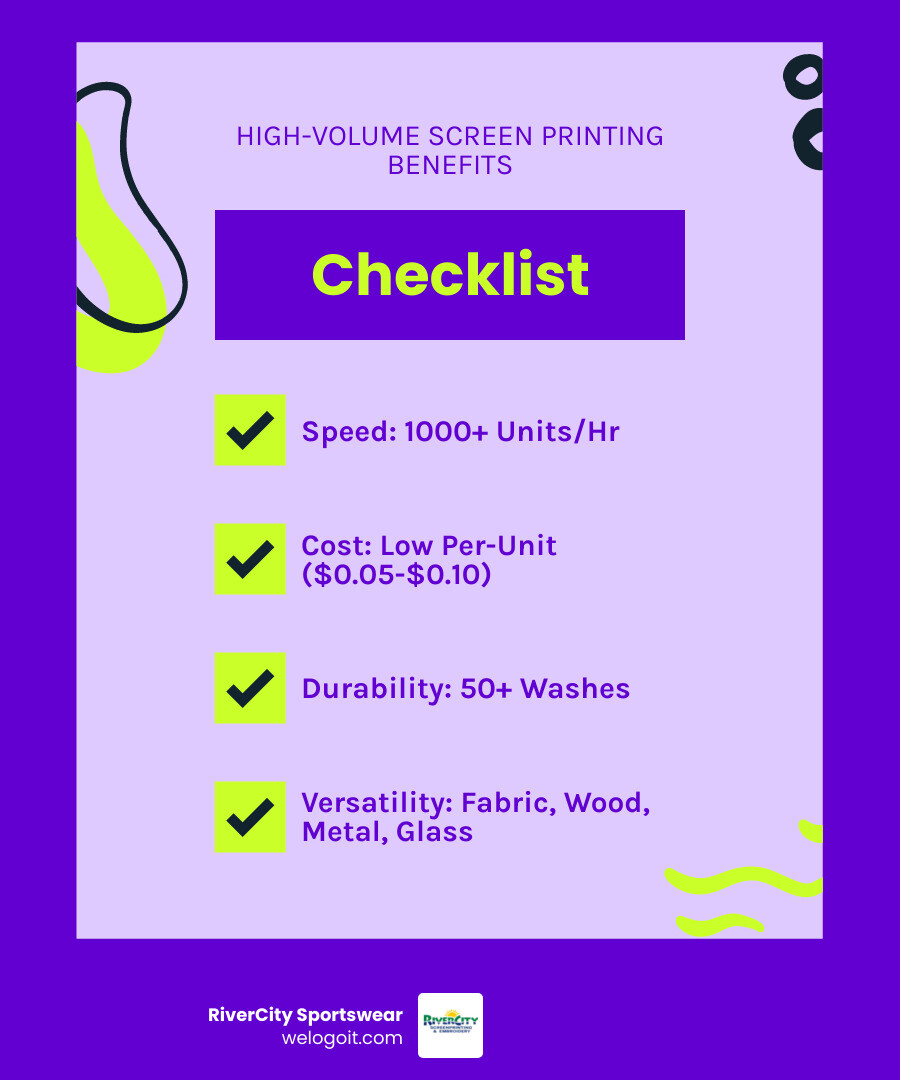

High volume screen printing is a specialized production method designed to create hundreds or thousands of custom-printed items efficiently and cost-effectively. Here’s what makes it the go-to choice for large orders:

- Speed: Automated presses produce 500–1,300+ garments per hour

- Cost: Per-unit costs as low as $0.05–$0.10 for materials on large runs

- Durability: Prints withstand 50+ washes without fading

- Versatility: Works on fabric, metal, wood, glass, and more

- Quality: Vibrant, opaque colors even on dark substrates

When you’re planning an event, outfitting a team, or launching branded merchandise, understanding your printing options matters. Digital printing and heat transfers have their place for small runs, but nothing matches screen printing for efficiency and value when you need volume. The setup costs—creating screens for each color—get distributed across your entire order, making each additional item cheaper to produce.

Screen printing delivers thick, durable ink layers that bond directly to the material. This means your custom t-shirts, tote bags, or promotional products will maintain their vibrant appearance through dozens of wash cycles and years of use. For businesses ordering 100+ items, this method typically offers the best combination of quality, speed, and price.

I’m Luke Sanders, CEO of RiverCity Screenprinting & Embroidery, where we’ve specialized in high volume screen printing for over 15 years, producing millions of custom apparel pieces and promotional products for businesses across Texas. Our operation handles everything from small event orders to massive corporate runs, and I’ve seen how the right printing method can make or break a project.

Why Screen Printing Excels for Bulk Orders

When it comes to outfitting a large team, promoting an event, or stocking merchandise for your business in San Marcos, Austin, or anywhere across Central and South Texas, you need a printing method that can keep up with demand without sacrificing quality or breaking the bank. This is precisely where high volume screen printing shines, offering unparalleled benefits over other printing techniques.

The secret lies in its inherent efficiency, robust print quality, and the ability to achieve striking visuals that last. We’re talking about more than just getting ink on a shirt; we’re talking about economies of scale, superior longevity, and vibrant, opaque colors that truly pop, even on dark fabrics. Screen printing isn’t just a process; it’s an investment in your brand’s lasting impression.

Unbeatable Cost-Effectiveness at Scale

One of the most compelling reasons businesses choose high volume screen printing is its remarkable cost-effectiveness. While there’s an initial setup cost involved in creating the screens for your design, this investment quickly pays off as your order size grows. Think of it like a one-time toll charge for an open road—once you’ve paid it, every additional mile (or in this case, every additional item) is practically free.

For instance, printing 1,000 t-shirts with a single color might incur a setup cost for screens and ink in the range of $50–$100. When spread across that many units, the per-unit material cost can plummet to an astonishing $0.05–$0.10 per item. Compare that to other methods where ink and material costs remain high for each individual print, and you’ll see why screen printing is the economical champion for bulk orders.

We understand that every penny counts for businesses in Texas, which is why we structure our pricing with significant price breaks. As your quantity increases, the per-unit cost decreases dramatically. This means that whether you need 100 shirts for a local Austin event or 10,000 for a statewide promotional campaign, you’re getting the best possible value. The automation inherent in modern screen printing processes further improves this cost-effectiveness by reducing labor, optimizing workflow, and maintaining consistent quality across every single piece.

Superior Durability for Long-Lasting Impressions

Nobody wants a custom shirt that fades or cracks after a few washes. That’s why durability is a cornerstone of high volume screen printing. Unlike digital prints that lay ink on top of the fabric and may begin to fade after just 10–20 washes, screen-printed items are built to last.

The magic happens during the ink application and curing process. Screen printing involves pushing thick layers of ink directly into the fibers of the material, rather than just sitting on the surface. This deep ink penetration creates a strong bond that can withstand the rigors of everyday wear and tear, including dozens of trips through the washing machine. We often tell our clients that a properly screen-printed t-shirt can endure 50 or more washes without losing its vibrant color or crisp clarity.

This exceptional longevity makes screen printing the industry standard for everything from work uniforms and team jerseys to promotional merchandise and apparel meant for resale. For businesses in Central and South Texas, where workwear needs to stand up to tough conditions or merchandise needs to represent your brand for years, screen printing delivers a superior, lasting impression. Our expertise ensures that every item we print is cured perfectly, guaranteeing that your designs remain as bold and beautiful as the day they were printed.

Achieving Vibrant, Opaque Colors

Ever tried to print a light color on a dark shirt with less effective methods? You’ll often end up with a dull, muted, or transparent result. Not so with high volume screen printing. One of its standout advantages is the ability to achieve incredibly vibrant and opaque colors, even when printing white ink on black t-shirts or bright hues on deep navy hoodies.

This is all thanks to the thick ink layers that screen printing applies. The stencil-based process allows for a generous deposit of ink, ensuring that colors are rich, bold, and fully opaque. This means your design will truly pop, providing excellent contrast and visibility regardless of the garment’s color.

To ensure perfect color matching for your brand, we use the Pantone Matching System (PMS). This universal color language allows us to precisely mix inks to match your specific brand colors, guaranteeing consistency across all your printed items, whether it’s a single order of 100 shirts or a recurring run of 10,000. Our ink department carefully pulls and stations stock inks or custom mixes requested PMS colors to achieve the exact shade you envision. This attention to detail means you can count on color consistency across every batch, maintaining your brand’s integrity with every print.

The High Volume Screen Printing Process: From Setup to Shipping

Starting on a high volume screen printing project is an exciting journey, and understanding the process from start to finish can help you appreciate the precision and efficiency involved. At RiverCity Sportswear, we’ve refined our workflow to ensure seamless production, from the initial artwork review to the moment your finished products are ready for delivery across Texas.

The backbone of our high-volume operation is automation. While a basic manual press might produce 50–100 items per hour, our state-of-the-art automatic machines are capable of churning out 500 to an astounding 1,300+ garments per hour for simple designs. This incredible speed is achieved through parallel processing, especially beneficial for multi-color designs, where different colors can be applied in rapid succession, significantly cutting down overall production time.

We pride ourselves on fast turnaround times, understanding that deadlines are critical for events and promotions in San Marcos and Austin. Our typical turnaround for screen printing is usually around two weeks once artwork and order details are approved, but for those urgent needs, rush orders can often be accommodated in as little as 3-5 business days. This kind of efficiency is only possible with the right equipment and a streamlined process.

Want to dive deeper into the kind of machinery that makes this magic happen? You can learn More on the equipment used in high-volume printing.

Pre-Press: Setting the Stage for Success

Before any ink touches a garment, a meticulous pre-press process ensures everything is perfectly aligned for a flawless high volume screen printing run. This stage is crucial for guaranteeing the quality and accuracy of your final product.

-

Artwork Review: We begin by thoroughly reviewing your submitted artwork. Our experienced art team examines it for printability, checking for fine lines, gradients, and overall complexity. If there are any elements that might not translate perfectly to screen printing, we’ll offer suggestions to optimize your design for the best possible outcome. Simpler artwork with fewer colors generally works best for screen printing, but we’re adept at making most logos, text, and graphics shine.

-

Art Proofing: Once the artwork is optimized, we create a digital art proof. This mock-up shows your design precisely how it will appear on your chosen garment style and color. It details exact imprint sizes and intended Pantone colors, serving as your final estimate for sizing and location. Your approval here is essential, ensuring we’re all on the same page before production begins.

-

Color Separation: For multi-color designs, we then undertake color separation. This is the process of deconstructing your artwork into its individual color components. Each color in your design will require its own separate film positive and, subsequently, its own screen.

-

Screen Creation (“Burning”): This is where the screens are literally “burned.” We coat a pre-stretched mesh screen with a photo-reactive emulsion. The film positive of your separated color is then placed on the emulsion-coated screen and exposed to high-intensity light. The light hardens the emulsion everywhere except where the opaque parts of your design block it. The unhardened emulsion is then washed away, leaving a perfect stencil of your design on the screen. Proper exposure creates durable stencils, vital for high-volume runs.

-

Screen Preparation: After drying, each screen is carefully prepped for production. This involves applying block-out to any emulsion areas outside the design to prevent tiny pin-holes—which could cause unwanted ink dots on your garment. We also tape off the screen edges to prevent ink leakage during printing.

-

Ink Mixing: Our ink department gets to work, pulling stock inks or custom mixing requested PMS (Pantone Matching System) colors. This ensures that the colors in your design are perfectly matched to your brand’s specifications, maintaining consistency across thousands of items.

-

Press Setup and Registration: Finally, the prepared screens are mounted onto our automatic presses. This is a critical step known as registration, where each screen is precisely aligned so that every color prints in its exact position, creating a cohesive, multi-color design. Our press operators consider variables like off-contact (the space between the screen and the garment), squeegee speed, angle, and durometer (squeegee blade hardness) to achieve the desired outcome. For efficiency in future orders, we carefully record these settings, making re-orders a fraction of the time to set up.

The setup time for a single-color design typically takes 30–60 minutes, while multi-color designs may require 2–3 hours. While this upfront investment in time is necessary, once everything is set, our presses can run at incredible speeds, making it exceptionally efficient for large batches.

The Engine Room: Essential Equipment for High Volume Screen Printing

The heart of any successful high volume screen printing operation lies in its equipment. For us, this means investing in cutting-edge machinery that guarantees speed, precision, and consistent quality for our clients across Texas.

Our arsenal for high-volume production includes:

- Automatic Screen Printing Presses: These are the workhorses of our operation. While a basic manual press yields 50–100 items per hour, our advanced automatic presses revolutionize output. Machines like the ROQ ECO can produce up to 1,300 garments per hour, and the ROQprint NEXT can handle up to 1,200 garments per hour. These presses come configured with numerous pallets (e.g., 8 to 20 pallets on the ROQprint NEXT, or 12 to 20 pallets on the ROQ ECO) and can print in a wide range of colors—from 1 to 18 colors depending on the model. This multi-station capability allows for parallel processing, where different colors or stages of a design are applied simultaneously, dramatically increasing efficiency for multi-color jobs.

- Conveyor Dryers: After ink is applied, it needs to be perfectly cured to ensure durability and longevity. Our high-capacity conveyor dryers are essential for this. Items pass through a heated chamber at a precisely controlled speed and temperature, ensuring the ink bonds permanently with the fabric. Gas conveyor dryers are particularly effective for this, handling large volumes with consistent results.

- Flash Cure Units: For multi-color designs, especially those requiring layering or specific effects, flash cure units are indispensable. These units are strategically placed between print stations on the automatic press, providing a quick burst of heat to partially cure an ink layer before the next color is applied. This prevents colors from smearing and allows for crisp, clean multi-color prints. Integrated flash units save significant time between color changes, a crucial factor in high-volume efficiency.

- Multi-Station Carousels: These are integral to automatic presses, allowing multiple garments to be loaded and printed in a continuous rotation. This design maximizes throughput and minimizes downtime, making the entire printing process incredibly efficient.

This sophisticated equipment, combined with our skilled operators, allows us to manage immense production volumes, ensuring that whether you need 100 t-shirts or 50,000 units per week, we can deliver with speed and quality.

Key Considerations for Your Large-Scale Project

Undertaking a large-scale printing project requires careful planning. Beyond the mechanics of printing, several factors influence the success and impact of your high volume screen printing order. At RiverCity Sportswear, we guide our clients in San Marcos, Austin, and across Central and South Texas through these considerations, from choosing the right materials to optimizing designs for bulk production and even considering environmental impact.

Material Versatility for Your High Volume Screen Printing Project

One of the most impressive aspects of screen printing is its incredible versatility across a vast array of materials. This means your high-volume project isn’t limited to just t-shirts; it can extend to almost any surface imaginable, making it perfect for diverse promotional merchandise.

We can effectively screen print on:

- Fabrics: Cotton and cotton-blend garments are often ideal, offering excellent durability and vibrant color results. However, modern screen printing techniques also excel on synthetic fabrics like polyester, silk, and viscose. We can print on t-shirts, hoodies, crewnecks, long sleeves, tank tops, caps, and tote bags—the possibilities for apparel are extensive.

- Canvas: Perfect for durable tote bags, art prints, or event signage.

- Wood: Think custom plaques, promotional items, or unique signage.

- Metal: Ideal for industrial parts, signage, or durable promotional products.

- Glass: Custom drinkware, mirrors, or decorative items can be beautifully screen printed.

- Plastic: From promotional pens and water bottles to custom signage, plastic is a common substrate.

- Textured Surfaces: Screen printing’s ability to lay down a thick layer of ink allows it to handle textured surfaces that digital printing often struggles with, such as certain types of canvas bags or rubber mats.

This extensive material compatibility ensures that whether you’re outfitting a team, creating merchandise, or producing branded promotional items, high volume screen printing offers the flexibility you need for your project in Texas.

Handling Complex Designs in Bulk

While high volume screen printing is incredibly versatile, understanding how design complexity interacts with the process is key to achieving the best results. Screen printing excels with designs that are simple to moderately complex, making it ideal for most logos, text, and graphics.

For very intricate designs featuring extremely fine lines, subtle gradients, or photorealistic detail, digital printing might be considered. However, our experienced art team can often optimize complex artwork to translate beautifully to screen printing. We work with you to simplify elements, adjust line thickness, or convert gradients into halftones (tiny dots that create the illusion of a gradient) to ensure your design prints crisply and clearly across thousands of units.

When you submit your artwork, we conduct a thorough review to determine its printability. If we anticipate any challenges, we’ll proactively offer suggestions for improvement, ensuring that the final product meets your expectations. Our goal is always to maximize the impact of your design while leveraging the efficiency and quality of high-volume screen printing. Utilizing vector art is always preferred, as it allows for scalability without loss of resolution, which is critical for large production runs.

Environmental Impact and Sustainable Options

As a responsible printing partner in Texas, we understand the growing importance of environmental considerations in manufacturing. High volume screen printing offers several sustainable options and practices that can minimize environmental impact.

Many modern screen printing inks are now water-based or eco-friendly. These alternatives reduce the use of harsh chemicals and volatile organic compounds (VOCs), making the printing process safer for our team and the environment. We actively use and recommend these options whenever possible.

Furthermore, screen printing is inherently efficient in its use of materials. We have policies in place to reuse excess ink, minimizing waste. Compared to digital printing, which can generate more energy waste and used ink cartridges, screen printing often produces less overall waste. The industry has also evolved, moving away from older, more toxic bichromate chemicals to safer, pre-sensitized chemicals for stencil creation, making the process more environmentally friendly.

We are committed to exploring and implementing sustainable practices throughout our operation, ensuring that your large-scale printing project aligns with both your brand values and environmental responsibility.

Frequently Asked Questions about High-Volume Printing

Is screen printing faster than other methods for high-volume orders?

Yes, absolutely! Once the initial setup is complete (which involves creating the screens for each color), our automatic screen printing presses can produce hundreds or even thousands of items per hour. This speed far outpaces other methods like digital printing or heat transfers, where each item is processed individually, making screen printing the clear winner for large batches. For example, our machines can hit production speeds of up to 1,300 garments per hour, a pace best by other techniques for bulk orders.

Why is screen printing more cost-effective for high volumes?

The economics of high volume screen printing are straightforward: setup costs are primarily upfront. You pay for the creation of screens for each color in your design. Once those screens are made, the cost to print each additional item drops dramatically. For large quantities, typically around 50 items or more, these initial setup costs are spread across the entire order, making the per-item cost significantly lower. In contrast, with methods like digital printing, the ink cost per item remains relatively constant, regardless of quantity, making them less cost-effective for bulk. We offer price breaks at various quantities, making larger orders increasingly economical.

How durable are screen-printed products?

Screen-printed products are renowned for their exceptional durability. The ink used in screen printing is designed to bond with the fabric fibers and is then heat-cured, creating a robust, long-lasting print. This means your design can withstand over 50 washes without significant fading, cracking, or peeling. This superior longevity makes screen printing the industry standard for apparel that needs to endure heavy use, such as work uniforms, team jerseys, or promotional items meant to last.

Conclusion

When considering your options for custom apparel and merchandise in San Marcos, Austin, or anywhere across Central and South Texas, the choice for large quantities becomes clear. High volume screen printing stands out as the superior method, offering an unbeatable combination of speed, cost-effectiveness, and durability.

We’ve explored how its inherent efficiency, powered by automatic presses, allows us to produce hundreds to thousands of items per hour, ensuring your project meets tight deadlines. We’ve seen how the initial setup costs are quickly offset by the low per-unit cost for large orders, making it the most economical choice. Furthermore, the robust ink application and curing process deliver prints that can withstand over 50 washes, ensuring your brand’s message remains vibrant and intact for years to come. Finally, its incredible versatility across a wide range of materials—from cotton t-shirts to metal signs—means your creative possibilities are virtually limitless.

For businesses, brands, and events requiring large quantities of custom apparel, high volume screen printing is the superior choice for quality and value. We’re here to help you master your next big project.

Start your custom screen printing project in San Marcos today.